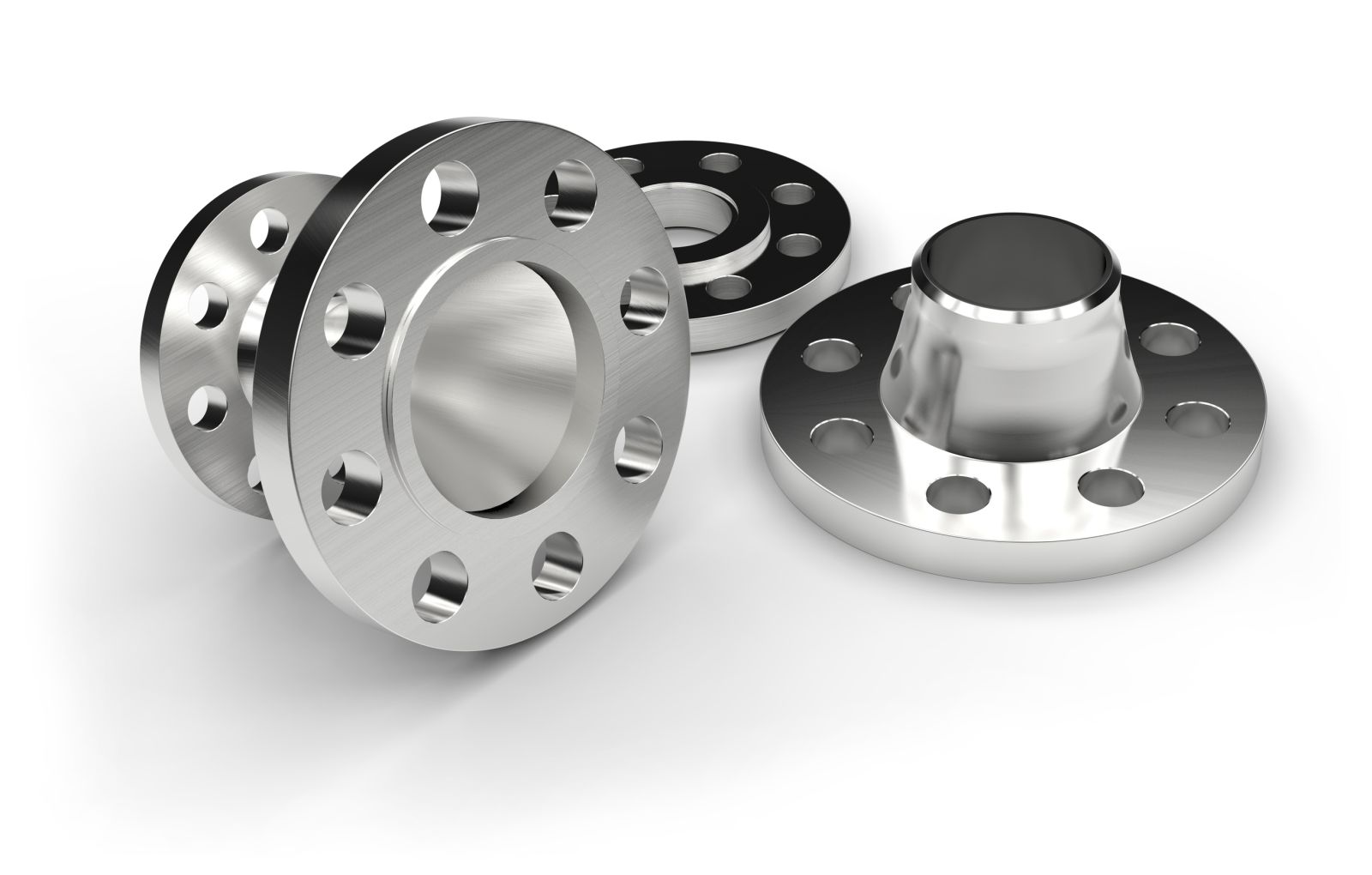

Titanium flange

Description

High-Quality Titanium Flanges by YICHOU

Product Description:

At YICHOU, we take immense pride in presenting our exceptional line of Titanium Flanges, meticulously designed and manufactured to meet and exceed the most rigorous industry standards. These flanges are the embodiment of precision engineering and metallurgical expertise, offering an unmatched level of performance and durability for an array of industrial applications.

Key Features:

-

Exceptional Material: Our Titanium Flanges are forged from the highest quality titanium, a metal renowned for its exceptional attributes. Titanium is not only exceptionally corrosion-resistant but also boasts an impressive strength-to-weight ratio, making it an ideal choice for demanding environments where both durability and lightness are paramount.

-

Versatile Types: Our product range encompasses a wide variety of flange types, including weld neck, slip-on, blind, lap joint, and socket weld, among others. This extensive selection ensures that we have the right solution for your specific needs, no matter the application or industry.

-

Wide Application Scope: YICHOU Titanium Flanges find utility across a spectrum of industries, from aerospace and marine to petrochemical and power generation. In the aerospace sector, they serve as critical components in aircraft engine assemblies due to their ability to withstand extreme conditions. In marine applications, our flanges thrive in the corrosive saltwater environment. Petrochemical facilities rely on them for their resistance to aggressive chemicals, while power generation plants trust their performance under high-temperature and high-pressure conditions.

-

Certified Quality: We hold ourselves to the highest quality standards, and our products bear the marks of internationally recognized certifications, including ISO 9001, ASME, ASTM, DIN, and JIS, assuring you of their superior quality, durability, and safety.

Product Specifications:

- Material: Our flanges are expertly crafted from high-purity titanium, ensuring optimal corrosion resistance, strength, and longevity.TA1 / GR1, TA2 / Gr2, TC4 / GR5, grade9, grade11, Grade12, titanium alloy flange.

- Types: Choose from a comprehensive range of flange types to match your exact requirements, from the robust weld neck flanges to the versatile slip-on flanges.

- Size Range: Our flanges are available in sizes ranging from 1/2" to 48", catering to a wide array of piping systems and dimensions.

- Pressure Class: These flanges are rated to meet ANSI 150-2500 and DIN PN6-PN160 standards, guaranteeing their ability to handle varying pressure levels.

- Temperature Range: They are designed to perform reliably across temperatures ranging from a frigid -50°C to a scorching 300°C.

- Surface Finish: Each flange boasts a smooth and rust-resistant surface, ensuring longevity and ease of maintenance.

- Packaging: Your order will be carefully packaged in secure wooden cases or customized to your specific packaging requirements.

- Qualification Certificates: Rest easy knowing that our flanges come with a stamp of quality assurance through ISO 9001, ASME, ASTM, DIN, JIS, and other industry certifications.

| Standard | Grades | Dimensions | Size Range | Class / Pressure Range | Flange Face Types |

|---|---|---|---|---|---|

| ASTM B381 | Grade 1, Grade 2 | ASME B16.5 | 1/2" - 24" | Class 150, 300, 600, 900, 1500, 2500 | Raised Face, Flat Face, Ring Type Joint (RTJ) |

| ASTM B381 | Grade 5 | ASME B16.47 | 26" - 60" | Class 150, 300, 600, 900 | Raised Face, Flat Face, Ring Type Joint (RTJ) |

| ASTM B381 | Grade 7, Grade 12 | ASME B16.36 | 1" - 3" | Class 300, 400, 600, 900, 1500, 2500 | Male and Female Face, Tongue and Groove |

| ASTM B381 | Grade 23 | Custom | Custom | Custom | Custom |

| DIN 17850 | Grade 2, Grade 5 | DIN 2632, 2633 | DN10 - DN1200 | PN10, PN16, PN25, PN40 | Type 01 (Plate), Type 02 (Loose Plate), Type 05 (Blank) |

| JIS B 3811 | Ti-CP, Ti-6Al-4V | JIS B 2220 | 10A - 1500A | 5K, 10K, 16K, 20K, 30K | Raised Face, Flat Face |

| MSS SP-43 | Grade 7, Grade 12 | MSS SP-44 | 2" - 48" | SCH 10S, SCH 40S | Weld Neck, Slip-On, Socket Weld |

| ASME B16.9 | Grade 2, Grade 5 | ASME B16.9 | 1/2" - 48" | SCH 10, SCH 40, SCH 80 | Lap Joint, Threaded, Blind, Socket Weld, etc |

Common Applications:

Our Titanium Flanges have proven their mettle in a multitude of applications, including but not limited to:

-

Aerospace: Within the aerospace industry, our flanges play a critical role in aircraft engine components, where precision engineering and the ability to withstand extreme conditions are non-negotiable.

-

Marine: Marine environments, notorious for their corrosive saltwater conditions, find a reliable ally in our titanium flanges, ensuring long-term durability and performance.

-

Petrochemical: In the petrochemical sector, where exposure to aggressive chemicals is routine, our flanges stand as guardians of safety, thanks to their resistance to corrosion.

-

Power Generation: Power generation facilities, operating under high-temperature and high-pressure conditions, rely on our flanges for their robustness and dependability.

.jpg)

FAQs (Frequently Asked Questions):

1. What are the advantages of using Titanium Flanges?

The primary advantages of Titanium Flanges include exceptional corrosion resistance, a remarkable strength-to-weight ratio, and longevity. These attributes make them indispensable in demanding industrial settings.

2. Are these flanges suitable for high-temperature environments?

Yes, our Titanium Flanges are designed to excel in high-temperature environments, making them an ideal choice for various industrial processes where heat resistance is crucial.

3. Do you offer custom sizes and configurations?

Absolutely! We understand that each project has unique requirements. We provide tailored solutions to meet your specific size, configuration, and material needs. Reach out to our expert team for personalized assistance.

4. Are your products compliant with international standards?

Without a doubt. Our commitment to quality extends to adherence to rigorous international standards and certifications, ensuring that our products meet and exceed industry benchmarks.

5. What is the typical lead time for orders?

Lead times may vary based on product specifications and order volume. Our customer support team will provide you with precise delivery information to accommodate your project timelines effectively.

Get Quote

- Visit our website: https://www.nbyichou.com/

- Email us: [email protected]

- Call us/whatsapp: +86 13355741031

- Chat with us: Live chat support available on our website