CNC Lathing and Turning

Description

Yichou Precision CNC Lathing and Turning: Crafting Excellence in Machining

.jpg)

Introduction to CNC Lathing and Turning

CNC Lathing and Turning are sophisticated machining techniques at the core of modern manufacturing. At Yichou, our CNC Lathing and Turning services represent a pinnacle of precision and innovation. These processes involve the use of computer numerical control (CNC) machines to shape raw materials into precise components. From aerospace to medical equipment, our expertise in CNC machining allows us to cater to a wide range of industries.

.jpg)

Advantages of CNC Lathing and Turning

Precision and Accuracy: CNC Lathing and Turning, driven by advanced software and automation, ensures remarkable precision and accuracy. Our CNC machines can produce intricate components with tolerances measured in microns, significantly reducing the margin of error. This level of precision is essential in industries where high-quality components are critical.

Versatility: The versatility of CNC Lathing and Turning at Yichou is one of our distinguishing features. We can work with an array of materials, including metals such as aluminum, brass, stainless steel, and more, as well as plastics like nylon, PEEK, and various engineering plastics. We're also equipped to handle exotic alloys, such as titanium and Inconel, making us a one-stop solution for diverse manufacturing needs.

.jpeg)

Efficiency: Efficiency is a hallmark of CNC machining. Our CNC machines operate 24/7, which means faster production times and shorter lead times for your projects. By streamlining processes and automating tasks, we effectively reduce costs and enhance the overall efficiency of our production.

Materials for CNC Lathing and Turning

We are committed to providing comprehensive solutions, and our proficiency in working with a wide spectrum of materials is a testament to that commitment:

Metals: We are adept at machining various metals, including but not limited to aluminum, brass, stainless steel, and more. Whether it's for automotive components or aerospace parts, our expertise extends to a broad range of metal materials.

Plastics: Nylon, PEEK, and other engineering plastics are frequently used in numerous industries. Our CNC capabilities extend to crafting intricate plastic components, adhering to the same high standards of precision and quality.

Exotic Alloys: For industries demanding specialized materials, we offer CNC machining services for challenging materials like titanium and Inconel. These materials are known for their high strength and resistance to extreme conditions, making them ideal for aerospace and other demanding applications.

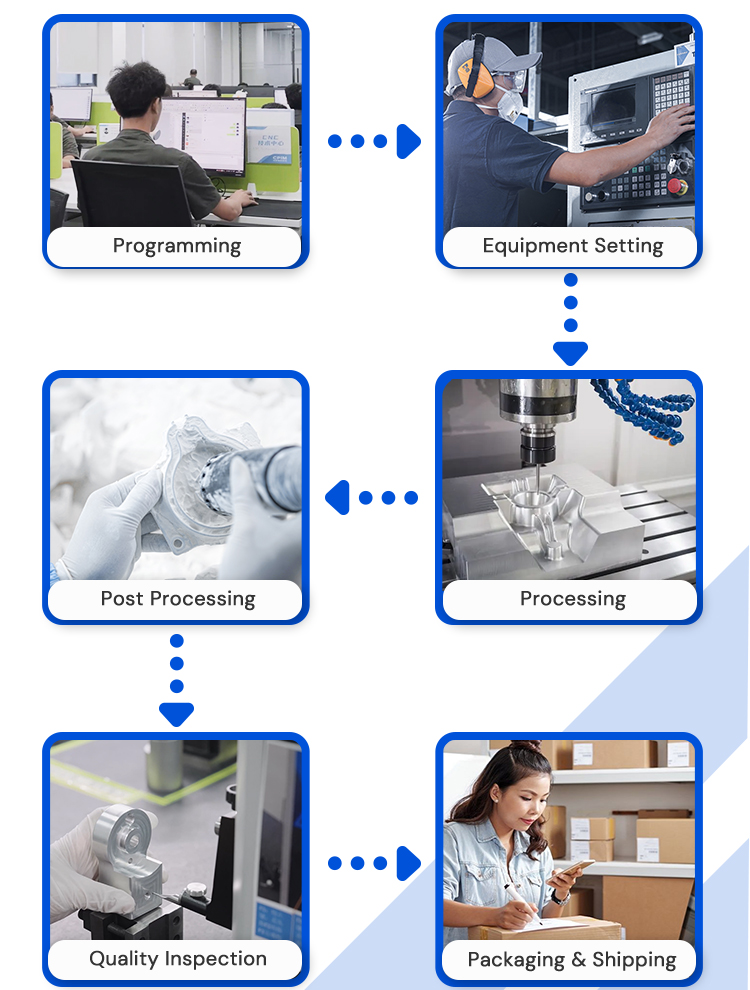

CNC Lathing and Turning Process Technology

Our advanced CNC Lathing and Turning technology is the backbone of our success, enabling us to meet and exceed client expectations:

Multi-Axis Machining: With our multi-axis CNC machines, we can create highly complex geometries. Whether it's for aeronautics or medical devices, our ability to handle intricate designs is unmatched.

Programming Expertise: Our skilled engineers excel in creating intricate, custom programs for CNC machining. This ensures that even the most complex designs are produced with unmatched precision and consistency.

Quality Control: Quality is paramount at Yichou. We employ stringent quality control checks at every stage of the process, from initial design to the final inspection. This guarantees that every component that leaves our facility meets the highest quality standards.

.jpg)

Price and Quality

At Yichou, our commitment to competitive pricing goes hand in hand with our unwavering dedication to quality. We understand the importance of cost-effectiveness in today's market. Our optimized processes not only ensure high-quality components but also cost-efficiency. By utilizing advanced CNC technology and streamlined manufacturing processes, we can provide our clients with competitive pricing without compromising on quality.

Applications of CNC Lathing and Turning

The versatility of our CNC Lathing and Turning services allows for a wide range of applications across various industries:

Automotive Industry: In the automotive sector, our precision components find their way into engines, transmission systems, and more. The precision and durability of our components play a crucial role in enhancing the performance and reliability of vehicles.

Aerospace Sector: In aerospace, precision is paramount. Our components are used in aircraft and spacecraft, contributing to their structural integrity, safety, and overall performance.

Medical Devices: For the medical device industry, we produce high-precision parts used in a range of equipment, from diagnostic devices to surgical tools. Our focus on quality and precision ensures that these critical medical components meet the highest standards of safety and performance.

.jpg)

FAQ 1: What are the key advantages of CNC Lathing and Turning at Yichou?

Keywords: CNC Lathing and Turning, Advantages, Precision, Versatility, Efficiency

CNC Lathing and Turning at Yichou offers several compelling advantages. Our precision machining process ensures unparalleled accuracy. We're known for our versatility, accommodating a wide range of materials. Efficiency is another hallmark, with shorter production times and cost-effectiveness.

FAQ 2: How does Yichou handle a variety of materials in CNC Lathing and Turning?

Keywords: Materials, CNC Lathing and Turning, Expertise

Our expertise in CNC Lathing and Turning extends to a wide spectrum of materials. From metals like aluminum, brass, and stainless steel to plastics such as nylon and PEEK, and even challenging exotic alloys like titanium and Inconel, we have the experience and technology to craft components with precision.

FAQ 3: What ensures the exceptional precision in CNC Lathing and Turning at Yichou?

Keywords: Precision, CNC Lathing and Turning, Multi-Axis Machining, Quality Control

Precision at Yichou is achieved through cutting-edge multi-axis machining technology. Complex geometries are handled with ease. Our rigorous quality control checks at every stage of the process guarantee that your components meet the highest precision standards.

FAQ 4: Can I expect cost-effective solutions from Yichou without compromising quality?

Keywords: Cost-effective, Quality, CNC Lathing and Turning, Competitive Pricing

Yes, Yichou is committed to delivering cost-effective solutions without sacrificing quality. Our efficient, automated processes and advanced CNC technology allow us to provide competitive pricing while maintaining the highest quality standards.

FAQ 5: What industries benefit from CNC Lathing and Turning services at Yichou?

Keywords: Applications, CNC Lathing and Turning, Industries, Automotive, Aerospace, Medical Devices

Our CNC Lathing and Turning services at Yichou cater to a wide range of industries. We serve the automotive industry, producing precision components for engines and transmission systems. Our components also play a crucial role in enhancing the performance and reliability of aircraft and spacecraft in the aerospace sector. Furthermore, we manufacture high-precision parts for medical devices, ensuring quality and reliability in the healthcare industry.

GET QUOTE

- Visit our website: https://www.nbyichou.com/

- Email us: [email protected]

- Call us/whatsapp: +86 13355741031

- Chat with us: Live chat support available on our website

.jpg)