Injection molding 1

Description

Welcome to YICHOU - Your Trusted Partner for Injection Molding and Customized Mold Technology

Introduction: At YICHOU, we take pride in being a leading parts manufacturer, offering top-notch injection molding and customized mold technology solutions to clients worldwide. Our cutting-edge processes and expertise allow us to cater to diverse industries, including aerospace, medical, shipbuilding, automobile, semiconductor, industrial, and more.

Our Technology and Capabilities: Our injection molding and customized mold technology enable us to manufacture high-quality parts with precision and efficiency. With state-of-the-art equipment and a team of skilled professionals, we can fulfill both small and large-scale orders while maintaining the utmost attention to detail.

Materials Processed: Our technology is versatile and can process a wide range of materials, including but not limited to:

- Various plastics (ABS, PP, PC, PE, etc.)

- Engineering plastics (PA, POM, PEEK, etc.)

- Metal alloys (Aluminum, Steel, etc.)

- Composite materials

- And more!

Advantages of Our Technology:

- Precision and Consistency: Our injection molding process ensures consistent and accurate part production, meeting stringent specifications.

- Cost-Effective: With efficient production processes, we offer competitive pricing without compromising on quality.

- Customization: We excel in creating tailor-made molds to meet specific client requirements, delivering unique solutions for diverse industries.

- Fast Turnaround: Our streamlined production allows us to deliver parts within short lead times, reducing waiting periods for our clients.

- Quality Assurance: We adhere to strict quality control measures, ensuring that each part meets international standards and passes thorough inspections.

Application Scope: Our injection molding and customized mold technology have applications in various industries, including:

- Aerospace: Components for aircraft and space exploration equipment.

- Medical: Medical device parts, diagnostic tools, and equipment.

- Shipbuilding: Maritime components and systems.

- Automobile: Automotive parts for interior, exterior, and engine systems.

- Semiconductor: Components for electronic and semiconductor manufacturing.

- Industrial: Parts for machinery and industrial equipment.

- And many more!

Qualification and Certificates: We are proud holders of various industry certifications, ensuring our commitment to quality and reliability. Our certifications include ISO 9001, ISO 13485 (for medical devices), and AS9100 (for aerospace).

.jpg)

Frequently Asked Questions (FAQs):

1. Can you handle large-volume orders? Absolutely! Our advanced injection molding process allows us to handle large-volume orders with ease while maintaining consistency in quality and timely delivery.

2. How do you ensure the accuracy of custom mold designs? Our experienced team of engineers uses cutting-edge design software and prototyping techniques to create precise custom mold designs. We thoroughly test and validate these designs before proceeding to production.

3. What materials are best suited for aerospace applications? We work with various aerospace-grade materials, such as aluminum alloys and high-strength composites, known for their lightweight and high-performance characteristics.

4. Do you offer post-processing services for the molded parts? Yes, we provide a range of post-processing services, including surface finishing, painting, and assembly, based on your specific requirements.

5. How do you ensure the quality of the molded parts? Quality is our top priority. We implement rigorous quality control measures throughout the production process, conducting inspections and tests to ensure each part meets the required standards.

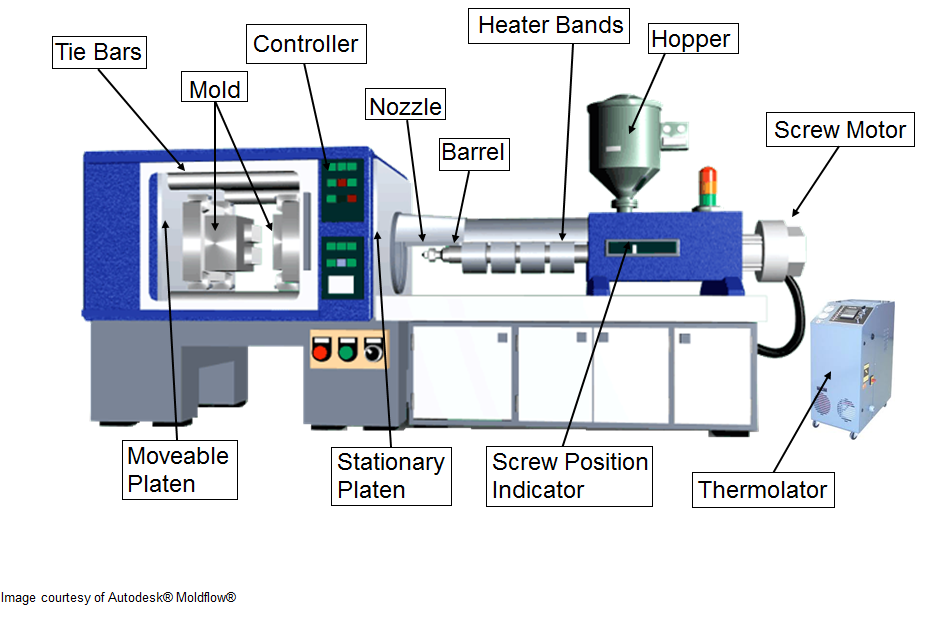

6.What is injection molding process?

Injection molding is a versatile manufacturing process used to produce plastic parts with precision and efficiency. Molten plastic is injected into a mold under high pressure, then cooled and solidified to form the desired shape. Experience our expert injection molding services for top-quality plastic components in various industries.

Partner with YICHOU for your injection molding and customized mold technology needs, and experience unmatched quality, precision, and reliability. Our expertise in diverse industries and dedication to customer satisfaction sets us apart as your ideal manufacturing partner. Contact us today to discuss your project requirements and take your business to new heights!

GET QUOTE

- Visit our website: https://www.nbyichou.com/

- Email us: [email protected]

- Call us/whatsapp: +86 13355741031

- Chat with us: Live chat support available on our website