Laser processing 3

Description

Laser Processing Services - Precision, Versatility, and Efficiency

Introduction

Welcome to YICHOU's cutting-edge Laser Processing Services! Our advanced laser technology offers precision, versatility, and efficiency, making it the ideal solution for a wide range of industries and applications. In this product details page, we will delve into the functional uses, compatible materials, advantages, application scope, qualification certificates, and more.

Functional Uses

Functional Uses

Laser processing is a highly versatile technique that enables the manufacturing of intricate and precise parts. It offers a myriad of functional uses, including:

-

Cutting: Our laser processing service excels in cutting various materials with unmatched accuracy and clean edges, ensuring minimal material wastage and high efficiency.

-

Engraving and Marking: Personalize your products or brand them with permanent markings using our laser engraving capabilities. It provides exceptional precision and quality.

-

Welding: The laser welding process ensures strong, durable, and precise joints, making it ideal for applications in industries like automotive, aerospace, and electronics.

-

Drilling: Laser drilling allows for precise and consistent hole drilling in various materials, enabling the creation of complex components.

Materials That Can Be Processed

Our laser processing services are compatible with a wide range of materials, including but not limited to:

- Metals: Steel, stainless steel, aluminum, copper, titanium, etc.

- Plastics: Acrylic, polycarbonate, ABS, PEEK, etc.

- Composites: Carbon fiber, fiberglass, etc.

- Ceramics: Alumina, zirconia, silicon carbide, etc.

Advantages of Laser Processing

Choosing YICHOU's Laser Processing Services comes with a plethora of advantages, such as:

-

Precision: Laser processing offers micron-level accuracy, ensuring the creation of intricate and detailed parts with minimal tolerances.

-

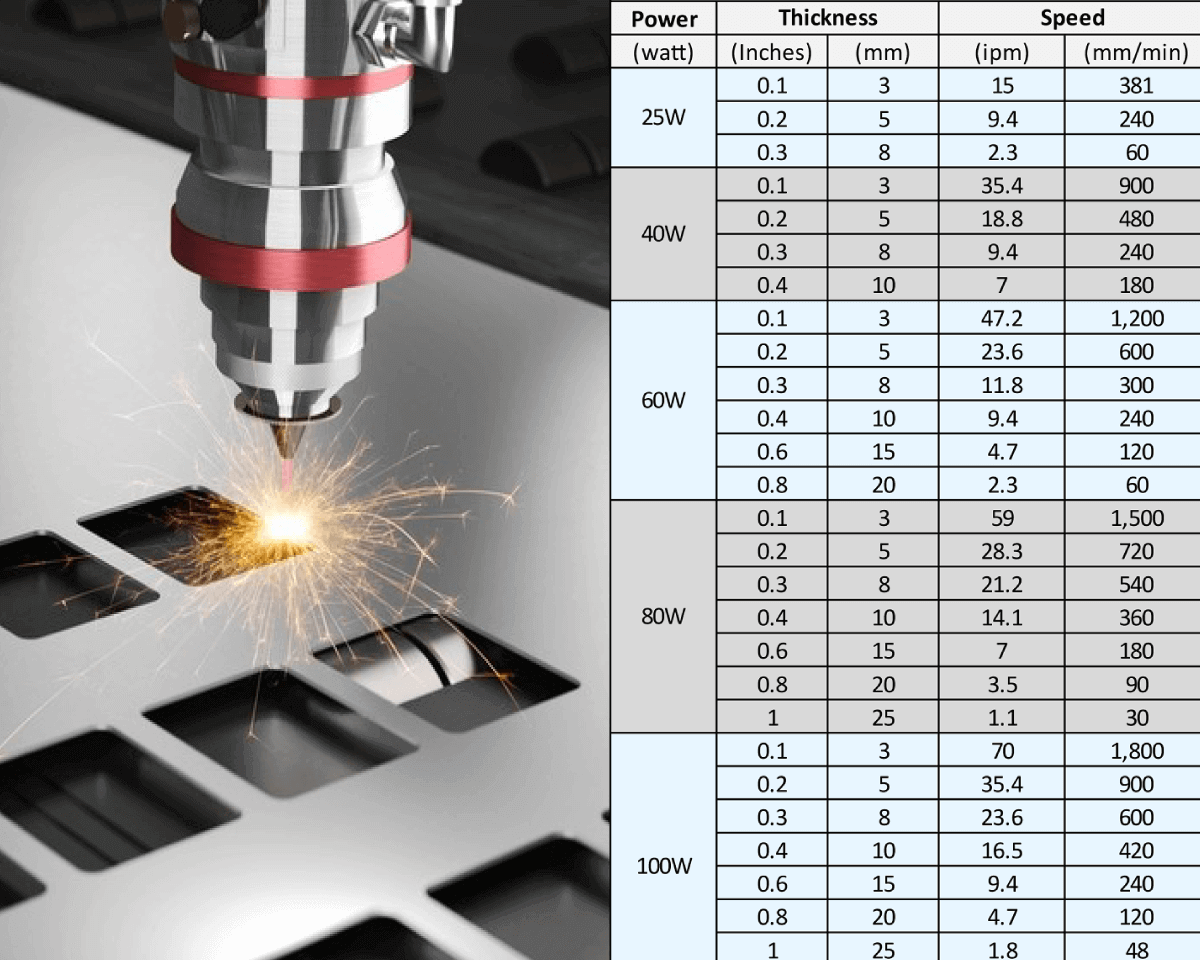

Speed: The high-speed capabilities of laser processing result in faster production cycles, reducing lead times and increasing overall productivity.

-

Versatility: From thin sheets to thick blocks, our laser technology can process various materials of different sizes and shapes.

-

Non-contact Process: As a non-contact technique, laser processing eliminates the risk of material deformation, enabling consistent quality across batches.

-

Cost-effectiveness: With reduced material wastage and increased efficiency, laser processing offers a cost-effective solution for manufacturing complex components.

Application Scope

YICHOU's Laser Processing Services find applications in numerous industries:

- Automotive: Precision parts, exhaust components, sensors, etc.

- Electronics: Microelectronic machining, PCB manufacturing, etc.

- Medical: Surgical instruments, implants, medical device components, etc.

- Aerospace: Aircraft parts, engine components, etc.

- Jewelry: Custom engravings, intricate designs, etc.

Qualification Certificates

Our Laser Processing Services adhere to the highest quality standards, and we hold the following qualification certificates:

-

ISO 9001: This certification ensures our commitment to quality management systems and customer satisfaction.

-

ISO 13485: For medical device manufacturing, this certificate validates our compliance with strict quality requirements.

-

AS9100: Aerospace industries rely on this certification to guarantee product quality and reliability.

-

RoHS Compliance: We comply with RoHS directives, ensuring the restriction of hazardous substances in our processes.

Frequently Asked Questions (FAQs)

-

Q: What is the turnaround time for laser processing orders? A: The turnaround time varies based on the complexity and quantity of the order. We strive to provide fast lead times without compromising quality.

-

Q: Can you handle large-scale production orders? A: Absolutely! Our state-of-the-art equipment and efficient processes enable us to handle both small and large-scale production runs.

-

Q: Is laser processing suitable for my specific material? A: Laser processing is compatible with a wide range of materials, but we recommend reaching out to our team to discuss your specific requirements.

-

Q: How does laser processing compare to traditional machining methods? A: Laser processing offers superior precision, reduced material wastage, and increased speed compared to many traditional machining methods.

-

Q: Do you provide design assistance for laser processing projects? A: Yes, we offer design support to optimize your parts for laser processing, ensuring the best possible results.

With YICHOU's Laser Processing Services, you can elevate your manufacturing capabilities, increase your Click-through rate, and boost your transaction rate by leveraging our cutting-edge technology and expertise. Contact us now to discuss your project requirements and discover the advantages of partnering with us!

With YICHOU's Laser Processing Services, you can elevate your manufacturing capabilities, increase your Click-through rate, and boost your transaction rate by leveraging our cutting-edge technology and expertise. Contact us now to discuss your project requirements and discover the advantages of partnering with us!

GET QUOTE

- Visit our website: https://www.nbyichou.com/

- Email us: [email protected]

- Call us/whatsapp: +86 13355741031

- Chat with us: Live chat support available on our website