The automobile is known as the pearl on the industrial crown. Its birth leads the human industrial system to the situation of great integration and great innovation, and has also become an important reference object to evaluate the comprehensive industrial strength of a country and region. Automobile production involves a large variety of technologies. Taking contemporary fuel vehicles as the analysis object, independent industries include metallurgy, casting, mechanical processing, electronic engineering, rubber chemical industry, etc. The most basic of which is undoubtedly casting process and mechanical processing. These two technologies are faced with various raw materials and blanks. The problem to be solved is to ' grow out of nothing ' of automobile products. After that, assembly, regulation, testing and other processes can be further considered.

In the development process of China 's automobile industry starting from zero and taking off rapidly, the most significant change is undoubtedly the progress of automobile parts casting technology and mechanical processing technology. However, at this stage, these two technologies can only be said to be ' bigger ' rather than ' stronger '. Especially in the field of high-strength automobile parts production, there is a big gap compared with the old automobile manufacturers ( Japan, the United States, Germany ). The book " Automobile Production Technology " ( Machinery Industry Press, October 1, 2020 ), edited by Yoichi Yoshino and translated by Ma Zhao, is based on the front line of Japanese automobile industry production. It divides automobile production into 16 key technical fields, and comprehensively introduces the casting process and machining technology of high-strength automobile parts from the perspective of " production site. " It has learning and enlightening value for front-line employees of China 's automobile industry, teachers and students of automobile manufacturing specialty in colleges and universities.

1 The main purpose is clear, and the production process and technology of automobile parts are comprehensively sorted out.

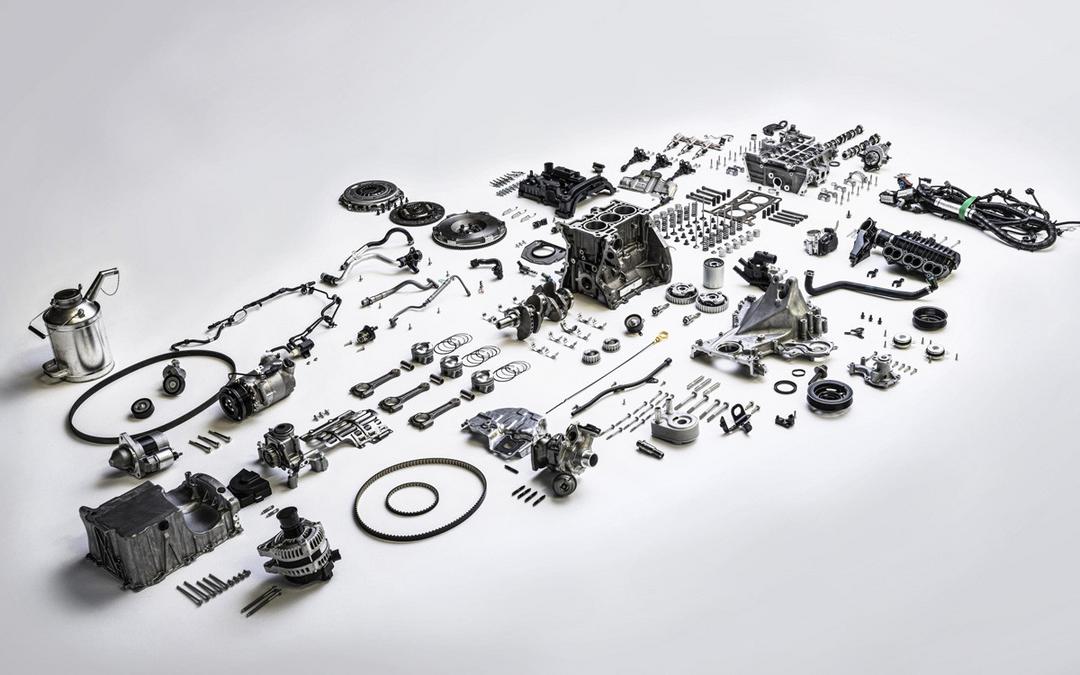

The editors of the book "Automotive Production Technology" are mainly frontline engineers and technical personnel in automotive production, which effectively guarantees the authority and practicality of the entire book's content. Objectively, the production of automotive parts involves a wide range of processes and technologies, but the main theme of this book is clear and focuses on the field of high-strength automotive parts production. On the one hand, a comprehensive review of casting technology, forging technology, sintering technology, stamping technology, resin synthesis technology, etc. has been conducted around the casting process of high-strength automotive components. On the other hand, a comprehensive review of cutting tool technology, connection technology, heat treatment technology, etc. has been conducted around the mechanical processing of high-strength automotive components. Intuitively, the casting of automotive components is closely related to mechanical processing. The casting process directly determines the difficulty and process of mechanical processing of automotive components, and whether the mechanical processing technology is advanced or not also affects the later assembly and assembly. China's automobile parts production has fully entered the digital era, and CNC technology is deeply embedded in the casting and mechanical processing of automobile parts. For example, common CNC machine tool solutions can control the precision of automobile parts at the micron level with the help of computer computing power, processing power, output capacity, etc. However, in order to achieve the production of this special product of "high-strength automotive parts", mechanical processing technology still needs to be further improved, that is, moving from the "digital era" to the "intelligent era", and utilizing the powerful control capabilities of artificial intelligence to further reduce the errors generated in the processing of high-strength materials. From this perspective, the automotive industry means a great integration and innovation of various technologies. The future high-strength automotive component machining platform should reach the level of chip processing.

.jpg)

2 Logically reasonable, based on linear thinking list auto parts production process

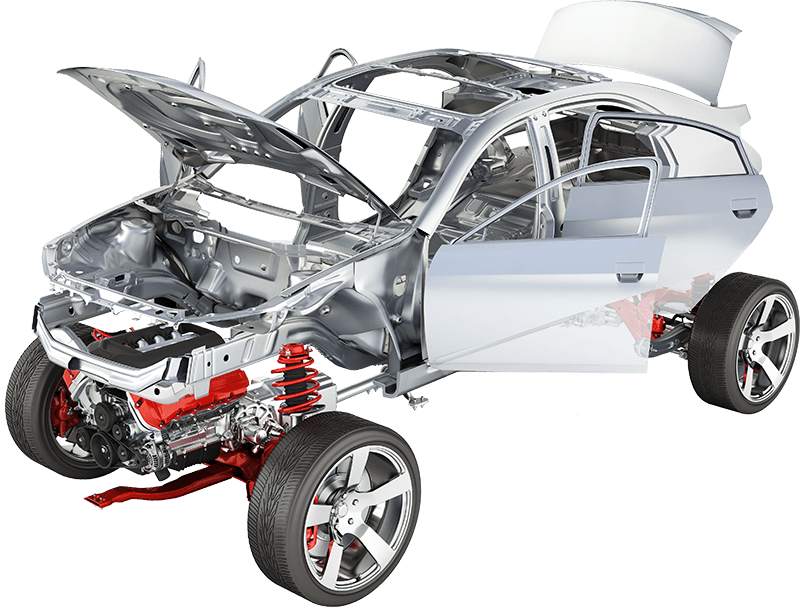

The book " Automobile Production Technology " has clear logic and reasonable structure. The book integrates 16 key links of automobile parts production into four modules. From the perspective of " vehicle manufacturing, " these four modules show the characteristics of linear thinking, that is, from scratch to show the production process of all parts of an automobile. The first is the casting process. The casting process of automobile parts mentioned in the book is the most advanced at present, such as ' advanced technology of aluminum casting process and equipment ', ' advanced technology of iron casting process and equipment ', etc. On this basis, the future development trend and new technical topics of casting technology are further analyzed. The second is machining technology, which also adopts the writing method of ' advanced technology innovation direction '. Thirdly, it is the assembly and assembly technology of automobile parts. In this process, the strength of automobile parts can be tested, and the defects of casting process and machining technology can be further improved according to the test feedback. Finally, the factory environment of automobile parts casting and machining is analyzed, focusing on energy saving and consumption reduction, which is also a focus of automobile production.

.jpg)

3 Practical point of view, from the perspective of mass production to explore auto parts production innovation

The book " Automobile Production Technology " emphasizes innovative ideas, which is very pragmatic for Chinese auto parts manufacturers. Especially from the perspective of automobile mass production, the " micro-innovation " of casting technology and machining technology can set off an industrial revolution, and have subversive consequences for the entire automobile industry and derive a new industrial pattern. For example, China 's automobile industry has experienced an unprecedented reversal in 2022. Whether it is production capacity, export volume, market recognition, domestic and foreign user penetration, etc., it has formed a rolling trend for the BBA brand ( German ) that has dominated the automobile list for many years. At the same time, Japanese, French and American automobile brands have also begun to realize the crisis. Behind all this, it is derived from ' energy innovation '.Electric vehicles abandon traditional racetracks and find new ways, and fuel vehicle power technology has been unable to compete with them. Correspondingly, under the premise of increasing safety concerns of automobile users, the strength of automobile parts can be improved through mechanical processing technology innovation and casting process innovation, which can also achieve the rolling effect of similar products and greatly enhance the competitiveness of China 's automobile products. Based on the traditional casting process and machining technology of automobile parts, this book puts forward a series of innovative directions, including the combination of technological innovation, surface modification technology innovation and stamping technology innovation. Grasping these innovative nodes and promoting product transformation will inevitably lead China 's automobile industry to a higher level.

\

\

Get Quote

- Visit our website: https://www.nbyichou.com/

- Email us: [email protected]

- Call us/whatsapp: +86 13355741031

- Chat with us: Live chat support available on our website