Are you a fan of home improvement projects but feel overwhelmed when it comes to understanding the intricacies of maintaining vacuum relief valves? Look no further! In this essential guide, we will break down everything you need to know about these important components of your plumbing system. From explaining how vacuum relief valves work to providing tips on routine maintenance, this article will equip you with the knowledge necessary to keep your valves functioning optimally. Our expert insights will help demystify the technical jargon and make the maintenance process a breeze. Whether you are a seasoned DIY enthusiast or a novice homeowner, this guide is designed to be accessible and easy to follow. We understand the importance of providing accurate information in an engaging and relatable manner, so you can confidently tackle any issues that may arise with your vacuum relief valves. So, grab your tools and get ready to master the art of understanding and maintaining vacuum relief valves. Let's dive in and empower you to take control of your home's plumbing system!

Title: Unlocking Efficiency: The Critical Role of Vacuum Relief Valves in Industrial Applications

In the dynamic landscape of industrial operations, ensuring optimal performance and safety is paramount. At the heart of this commitment lies the crucial role played by vacuum relief valves. These unsung heroes are pivotal in maintaining the delicate balance of pressure within industrial systems, preventing potentially catastrophic consequences. As industries evolve and technology advances, the importance of vacuum relief valves becomes even more pronounced. This blog explores the multifaceted significance of these valves in industrial applications, shedding light on their impact on operational efficiency, safety protocols, and overall system integrity.

Title: Demystifying Mechanisms: How Vacuum Relief Valves Safeguard Industrial Systems

Understanding the inner workings of vacuum relief valves is essential for any industry professional seeking to optimize their processes. These valves act as guardians, preventing the formation of vacuum conditions that could compromise the structural integrity of pipelines, storage tanks, and various industrial equipment. By intelligently responding to fluctuations in pressure, vacuum relief valves maintain equilibrium, ensuring a smooth and uninterrupted workflow. Delving into the intricacies of these mechanisms not only enhances operational knowledge but also empowers decision-makers to make informed choices for their specific industrial setups.

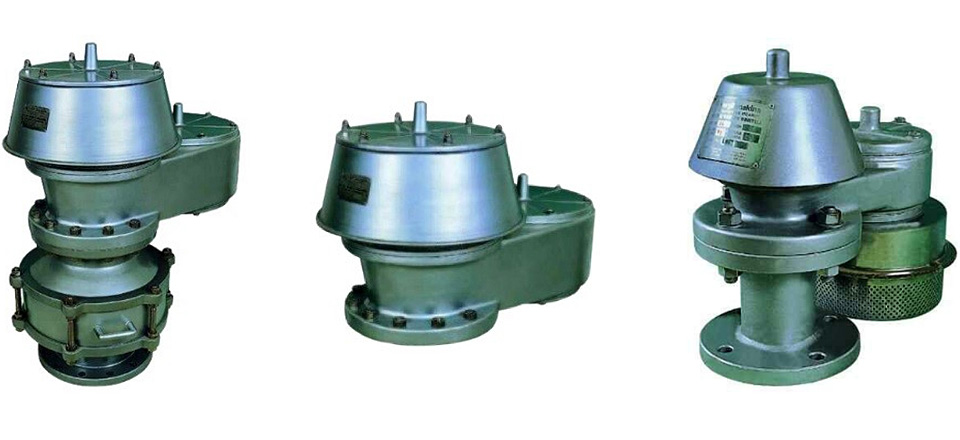

Title: Exploring Diversity: A Comprehensive Look at Common Types of Vacuum Relief Valves

The world of vacuum relief valves is diverse, offering a range of options tailored to meet the unique needs of different industries. From pilot-operated relief valves to direct-acting counterparts, each type brings its own set of advantages and applications. This section of the blog takes a deep dive into the common types of vacuum relief valves, providing insights into their design, functionality, and suitability for various industrial contexts. Armed with this knowledge, businesses can make strategic decisions when selecting the most fitting valve for their specific operational requirements.

Title: Navigating the Selection Process: Key Factors for Choosing Vacuum Relief Valves

Selecting the right vacuum relief valve is a critical decision that can significantly impact the efficiency and safety of industrial processes. In this segment, we explore the key factors that demand consideration when undertaking this decision-making process. From pressure ratings and material compatibility to application-specific requirements, understanding these factors ensures a meticulous and well-informed selection. By aligning the choice of vacuum relief valve with the unique demands of a given industrial application, businesses can not only enhance their operational capabilities but also fortify their commitment to safety standards.

Title: Ensuring Longevity: A Guide to the Installation and Maintenance of Vacuum Relief Valves

Efficient and reliable industrial operations hinge on the proper installation and maintenance of critical components, and vacuum relief valves are no exception. This section elucidates the best practices for installing these valves, emphasizing the importance of precision to guarantee optimal functionality. Furthermore, it explores the ongoing maintenance routines that ensure longevity and peak performance. By delving into the intricacies of installation and maintenance, industries can proactively safeguard their systems and reduce the risk of unexpected downtime.

Title: Troubleshooting Uncharted Territory: Addressing Common Issues with Vacuum Relief Valves

Even with meticulous installation and regular maintenance, vacuum relief valves may encounter issues that necessitate troubleshooting. This segment navigates through common challenges faced by these valves, offering insights into the root causes and effective solutions. By empowering industry professionals with troubleshooting knowledge, this information aids in the swift identification and resolution of issues, minimizing disruptions and contributing to the overall resilience of industrial processes.

Title: Preserving Performance: Best Practices for Maintaining Vacuum Relief Valves

Maintaining vacuum relief valves is not merely a routine task; it is a proactive strategy to preserve their performance and extend their lifespan. This portion of the blog uncovers best practices for ongoing maintenance, including periodic inspections, lubrication, and calibration. Highlighting the symbiotic relationship between meticulous maintenance and consistent performance, industry stakeholders can adopt these best practices to enhance the reliability and efficiency of their vacuum relief valves.

Title: Navigating Safety: Essential Considerations When Working with Vacuum Relief Valves

Safety is paramount in any industrial setting, especially when working with critical components such as vacuum relief valves. This section outlines key safety considerations, from proper handling procedures during installation to precautions for maintenance activities. By integrating these safety measures into standard operating protocols, businesses can foster a secure working environment, mitigating potential risks and ensuring the well-being of personnel involved in the installation and maintenance of vacuum relief valves.

Conclusion: The Crucial Role of Regular Inspection and Maintenance in Industrial Safety

In the grand tapestry of industrial operations, the importance of regular inspection and maintenance of vacuum relief valves cannot be overstated. As this blog journey concludes, it reiterates the symbiotic relationship between proactive maintenance practices and the overall safety and efficiency of industrial processes. By investing time and resources into systematic inspection and maintenance, industries not only protect their valuable assets but also fortify their commitment to a culture of safety, resilience, and uninterrupted productivity.

Why choose yichou for manufacturing vacuum Relief Valves?

Choosing Yichou for manufacturing vacuum relief valves offers a host of advantages, rooted in their commitment to quality, innovation, and customer satisfaction. Here are some compelling reasons to consider Yichou for your vacuum relief valve needs:

-

Proven Expertise: Yichou boasts a track record of excellence in the manufacturing industry. With years of experience, their team has honed their skills and expertise, positioning them as leaders in the production of vacuum relief valves. Their deep understanding of industry dynamics ensures that the valves meet the highest standards of performance and reliability.

-

Cutting-Edge Technology: Yichou embraces the latest technological advancements in valve manufacturing. By integrating cutting-edge technologies into their production processes, they deliver products that are not only efficient but also incorporate innovative features to address the evolving needs of industrial applications. This commitment to technological excellence sets Yichou apart in the market.

-

Customization Options: Yichou recognizes that different industries have unique requirements. They offer a range of customization options, allowing clients to tailor vacuum relief valves to their specific needs. Whether it's adjusting pressure settings, materials, or design elements, Yichou collaborates with clients to create solutions that seamlessly integrate into their systems.

-

Quality Assurance: Yichou prioritizes quality assurance throughout the manufacturing process. From raw material selection to the final product inspection, each step undergoes rigorous quality control measures. This unwavering commitment to quality ensures that Yichou's vacuum relief valves not only meet industry standards but also exceed expectations in terms of durability and performance.

-

Global Compliance: Yichou's dedication to global quality standards and compliance is evident in their products. The vacuum relief valves undergo testing and certification processes to ensure adherence to international industry standards and regulations. This commitment instills confidence in clients, assuring them that Yichou's valves comply with the highest safety and performance benchmarks.

-

Responsive Customer Support: Yichou understands the importance of responsive customer support in the manufacturing industry. Their team of experts is readily available to assist clients with inquiries, technical support, and after-sales service. This commitment to customer satisfaction fosters long-term relationships and reinforces Yichou as a reliable partner in the manufacturing process.

In conclusion, choosing Yichou for manufacturing vacuum relief valves ensures a holistic solution that encompasses quality, innovation, customization, and excellent customer support. Their proven track record, commitment to technological advancements, and dedication to customer satisfaction make Yichou a trusted partner for industries seeking reliable and high-performance vacuum relief valves.

Q1: Where should a vacuum relief valve be installed? A: Vacuum relief valves should be strategically installed at high points in piping systems or storage tanks to prevent the formation of vacuum conditions. These valves are typically placed where air might be trapped, ensuring efficient and safe operation. Specific installation locations may vary based on the unique characteristics of the industrial or plumbing system.

Q2: What causes a vacuum relief valve to leak? A: Vacuum relief valve leaks can be attributed to several factors. Common causes include dirt or debris accumulation, wear and tear on internal seals, or improper installation. Regular maintenance, including cleaning and inspection, is crucial to prevent leaks. If a leak is detected, it's advisable to assess the condition of the valve, replace any damaged components, and ensure proper installation for optimal performance.

Q3: What is the function of a vacuum relief valve? A: The primary function of a vacuum relief valve is to prevent the creation of vacuum conditions within a system. These valves allow atmospheric air to enter the system when needed, maintaining balanced pressure and preventing potential damage to pipes, tanks, or equipment. By intelligently responding to changes in pressure, vacuum relief valves contribute to the overall safety and efficiency of industrial processes.

Q4: Do I need a vacuum relief valve on a water heater? A: Yes, it is recommended to have a vacuum relief valve on a water heater. These valves play a crucial role in preventing the formation of a vacuum inside the water heater, which can occur when hot water is drawn from the system. The vacuum relief valve allows air to enter, preventing damage to the water heater tank and ensuring the continued efficient operation of the system. Local building codes may specify the requirements for vacuum relief valves on water heaters, so it's essential to adhere to these regulations.

GET QUOTE

- Visit our website: https://www.nbyichou.com/

- Email us: [email protected]

- Call us/whatsapp: +86 13355741031

- Chat with us: Live chat support available on our website