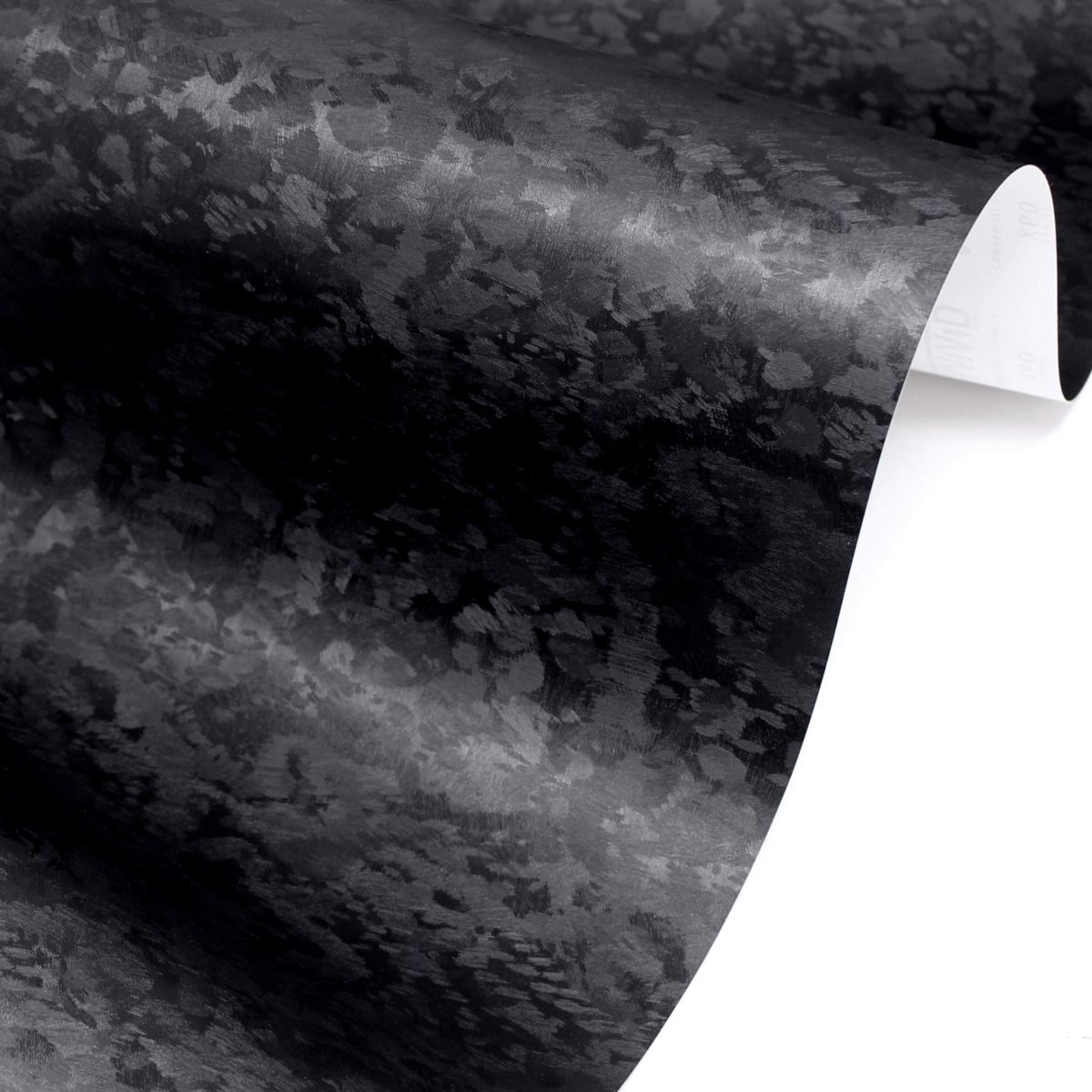

Innovation has propelled industries forward, but the breakthroughs in material technology truly revolutionize how we design and build. Enter forged carbon fiber wrap – a marvel that has been making waves in various fields, from automotive to aerospace. This lightweight, high-strength material combines the beauty of carbon fiber with the flexibility and molding capabilities of traditional wraps, unlocking a new level of possibilities for manufacturers and designers alike. With its distinct marbled appearance and exceptional strength-to-weight ratio, forged carbon fiber wrap is rapidly gaining popularity as an alternative to traditional materials. It offers superior performance in terms of rigidity, durability, and resistance to impact, making it an ideal choice across industries where weight reduction and enhanced structural integrity are critical. Just imagine the potential applications – from improved fuel efficiency in automobiles to stronger, lighter aircraft components. With forged carbon fiber wrap, the future of design is taking shape. Its versatility, efficiency, and aesthetic appeal make it an attractive option for those in search of innovative solutions. Experience the wonders of forged carbon fiber wrap and unlock a world of endless possibilities in manufacturing and design. Get ready for a groundbreaking leap into the future.

Understanding the benefits of forged carbon fiber wrap

Forged carbon fiber wrapping, as a cutting-edge technology in carbon fiber manufacturing, brings many outstanding benefits. First of all, it not only inherits the lightweight and high-strength characteristics of traditional carbon fiber but also shows an unparalleled unique texture in appearance. Through the forging process, the fiber structure of the carbon fiber becomes more tightly ordered, improving the overall mechanical properties. This makes the product wrapped in it not only lighter in weight but also significantly improved in durability and resistance to pressure.

In automobile manufacturing, the use of forged carbon fiber wrapped technology of body parts such as doors, engine covers, etc., not only reduces the weight of the vehicle, improves fuel efficiency, but also greatly enhances the stability of the vehicle structure, thus providing a higher level of driving safety. In addition, its excellent chemical stability and corrosion resistance also enable it to perform well in extreme environments, providing innovative solutions for the future development of the automotive industry.

Exploring the applications of forged carbon fiber wrap

Forging carbon fiber winding technology is widely used in many fields, promoting technological innovation in these fields. In the aerospace sector, this technology is used to make structural parts of aircraft and spacecraft, such as wings and fuselages. Compared with traditional materials, forged carbon fiber packaging can not only reduce the total weight of the aircraft, and improve fuel efficiency but also have better tensile strength, making the aircraft more stable and reliable in high-speed flight and complex environments.

In sporting goods manufacturing, forged carbon fiber winding technology also brings new possibilities for the design of sports equipment. For example, the frame of a high-end bicycle, the body of a golf club, etc., by forging carbon fiber packaging, not only reduces the weight of the equipment but also improves the rigidity and stability of the material, providing a higher level of performance and control for the athlete.

The science behind forged carbon fiber wrap

Behind forged carbon fiber wraps are advanced scientific principles and manufacturing techniques. During the forging process, under high temperatures and pressure, the carbon fiber structure can be rearranged to form a tighter network structure. This not only increases the density and strength of the material but also gives it excellent wear resistance and impact resistance. In addition, the process of forging carbon fiber wraps can achieve the manufacture of complex shapes to meet the precise shape requirements of different products.

From the perspective of materials science, forged carbon fiber wrapping technology is promoting the research and innovation of carbon fiber materials. Through the in-depth study of the fiber arrangement and crystal structure of carbon fiber, scientists have made remarkable progress in the manufacture of stronger, lighter, and more durable carbon fiber materials. This lays a solid foundation for the development of more efficient and innovative carbon fiber wrapping technologies in the future.

How to install forged carbon fiber wrap

Installing forged carbon fiber wraps requires careful planning and professional operation. First, make sure the surface to be wrapped is clean, flat, and free of any obstructions. Cleaning the surface can be done using a special cleaner that ensures the removal of all dust and grease to ensure the adhesion of the package.

Next, according to the shape and size of the product, cut the appropriate forged carbon fiber wrapping material. During the application process, professional glue or adhesive is used to ensure that the carbon fiber wrap is evenly covered on the target surface. To ensure the tightness and flatness of the package, tools such as scrapers and rollers can be used for construction.

During the installation process, try to avoid the formation of bubbles or wrinkles to ensure the appearance and performance. Apply appropriate pressure and temperature controls to facilitate the bonding process by the product instructions or the guidelines provided by the manufacturer.

Finally, let the package dry and cure completely, ensuring that it binds firmly to the underlying surface. After installation, periodically check and ensure that the forged carbon fiber wrap is in good condition to maintain its performance and appearance.

Maintenance and care for forged carbon fiber wrap

To maintain the superior performance and appearance of forged carbon fiber wrap, regular maintenance and maintenance is essential. First, clean the surface regularly, use mild cleaners and soft cloths, and avoid the use of harmful chemicals to prevent damage to the appearance and structure of the package.

Check the overall condition of the carbon fiber package regularly to make sure there are no cracks, wear, or other damage. Especially in high-intensity use or extreme environments, more frequent checks should be performed if any damage is found, and repair or replace the damaged part promptly to prevent further expansion of the problem.

Avoid carbon fiber packages exposed to strong ultraviolet light for a long time, as well as extreme temperatures, which may cause color changes or performance degradation of the package. When not in use for a long time, you can consider the use of a professional protective cover to extend its life.

Comparing forged carbon fiber wrap to other materials

Forged carbon fiber wraps have unique advantages over other materials. Compared to traditional metal materials, forged carbon fiber wraps have higher strength and stiffness, while being lighter. This makes it widely used in automotive, aerospace sports equipment, and other fields to improve product performance.

Compared to fiberglass, forged carbon fiber wraps are not only lighter but also have higher tensile strength and rigidity. This makes it more prominent in applications where lightweight and high strength is required, such as high-end bicycles and sports equipment.

In addition, the manufacturing process of forged carbon fiber wraps is more environmentally friendly than traditional resin composites because it does not require the use of large amounts of solvents and chemicals. This is in line with modern society's pursuit of sustainable and environmentally friendly products.

By comparing forged carbon fiber wrapping with other materials, we can more clearly recognize its unique advantages and excellent performance in different application fields.

|

peculiarity |

Forged carbon fiber wrap |

Conventional metal |

Glass fibre |

Resin composite |

|

intensity |

high |

Middle and low |

In the |

Medium to high |

|

rigidity |

high |

high |

In the |

Medium to high |

|

weight |

light |

heavy |

light |

In the |

|

Appearance effect |

Unique and noble |

tradition |

Clear and light |

Varied, depending on the material |

|

Environmental protection of the manufacturing process |

Relatively environmentally friendly |

Traditional methods produce waste |

Relatively environmentally friendly |

Need chemicals |

|

Corrosion resistance |

high |

low |

In the |

In the |

|

cost |

Relatively high |

normal |

Relatively low |

Subject to specific requirements |

|

plasticity |

higher |

normal |

high |

high |

Where to buy forged carbon fiber wrap

As a carbon fiber processing plant in China, YICHOU provides you with a one-stop solution for forging carbon fiber wrapping. Based on our expertise and high-quality materials, we are committed to providing customers with customized and innovative carbon fiber wrapping products. You can get more information from the sales team and submit custom requirements. YICHOU, your trusted carbon fiber manufacturing expert, infuses your products with superior performance and unique charm.

Case studies and success stories of forged carbon fiber wrap

At YICHOU, we are proud to offer a wide range of case studies and success stories of forged carbon fiber winding. Through our technological innovation and the craftsmanship of our professional team, we have successfully provided outstanding solutions to customers in multiple industries. From automotive parts to aerospace structures to sports equipment, our forged carbon fiber wraps have achieved remarkable results in lightweight, strength enhancement, and design innovation.

You can learn more about the case details and success stories by visiting our official website. These case studies not only demonstrate YICHOU's outstanding capabilities in the field of forging carbon fiber wraps but also provide you with an in-depth understanding of the practical application of the product. Choose YICHOU, choose successful partners, and give your products greater competitiveness.

Conclusion: Harnessing the potential of forged carbon fiber wrap

Combined with YICHOU's strong technical strength and extensive experience, we have summed up the potential of forging carbon fiber wraps for you. By opting for YICHOU's custom service, you'll get innovative, high-performance carbon fiber wraps that give your products a competitive edge. Not only that, but our success stories demonstrate the remarkable potential of forged carbon fiber wraps to improve product performance, reduce weight, and increase design flexibility.

At YICHOU, we are not only a carbon fiber processing plant, but also your successful partner. Choose YICHOU and let us start a new chapter in carbon fiber wrapping, bringing unlimited possibilities to your products.

1. Is Forged Carbon Fiber Superior to Traditional Methods?

Discover the advantages of forged carbon fiber over traditional methods in our manufacturing process at YICHOU. We delve into the unique properties and benefits that make forged carbon fiber a superior choice for various applications. Learn how our expertise in this advanced manufacturing technique sets us apart, ensuring top-quality components for your specific needs.

2. Can Carbon Fiber Be Forged?

Unlocking the Potential at YICHOU Explore the innovative manufacturing capabilities at YICHOU as we answer the question of whether carbon fiber can be forged. Learn about the intricacies of our forging process, how it enhances the material's properties, and the diverse applications where forged carbon fiber can be employed. Gain insights into the cutting-edge techniques that define our commitment to excellence.

3. Is Forged Carbon an Expensive Material Option?

Understand the cost dynamics of forged carbon fiber with YICHOU. We break down the factors that contribute to the pricing of forged carbon components and how our manufacturing processes optimize efficiency without compromising quality. Explore the cost-effectiveness of choosing forged carbon with YICHOU for your specific applications.

4. Are Carbon Fiber Hood Wraps Worth the Investment?

Delve into the considerations of investing in a carbon fiber hood wrap with insights from YICHOU. Learn about the aesthetic, performance, and durability benefits of choosing carbon fiber wraps for automotive applications. We provide a comprehensive analysis of whether the investment aligns with your goals, and how YICHOU's expertise ensures a worthwhile and lasting solution.

GET QUOTE

- Visit our website: https://www.nbyichou.com/

- Email us: [email protected]

- Call us/WhatsApp: +86 13355741031

- Chat with us: Live chat support available on our website