Introduction:

Overview of Hastelloy Alloys: Hastelloy is a family of high-performance nickel-based alloys, known for their exceptional resistance to corrosion, durability, and ability to withstand extreme temperatures. Due to its unique chemical composition, primarily consisting of nickel, molybdenum, and chromium, Hastelloy offers superior protection against corrosive environments, particularly in situations involving highly aggressive chemicals and oxidizing or reducing conditions. The alloy's ability to retain strength and resist chemical degradation even in high-heat scenarios makes it one of the most reliable choices for demanding industrial applications.

Importance in Industrial Applications: Hastelloy alloys have become indispensable in a variety of industries that require materials capable of enduring severe environmental conditions. Industries such as chemical processing, aerospace, oil and gas, marine engineering, and power generation rely on Hastelloy for its corrosion resistance and high strength. For example, in chemical plants, where exposure to harsh acids and corrosive substances is common, Hastelloy is used for critical components such as reactors, heat exchangers, and piping systems. Its role in high-temperature environments, such as gas turbines and nuclear reactors, also underscores its importance in modern engineering, where performance and durability under stress are non-negotiable.

1. What Material is Hastelloy?

Definition and Composition: Hastelloy refers to a group of nickel-based superalloys primarily composed of nickel, molybdenum, and chromium. These elements are combined to create a material that excels in environments where corrosion, high temperatures, and aggressive chemicals would quickly degrade most other metals. Nickel provides Hastelloy with its outstanding corrosion resistance, molybdenum improves its resistance to reducing acids, and chromium enhances its ability to withstand oxidizing environments. This combination makes Hastelloy a go-to material for industries facing highly corrosive and extreme conditions.

Main Properties: The primary strength of Hastelloy lies in its high resistance to corrosion across a wide range of environments, including those involving hydrochloric acid, sulfuric acid, and chlorine gas. Hastelloy maintains its mechanical integrity and strength at elevated temperatures, making it ideal for use in high-temperature processing and equipment. It also exhibits resistance to localized corrosion (like pitting and crevice corrosion) and stress corrosion cracking, which are common in harsh industrial environments.

Key Grades of Hastelloy:

- Hastelloy C-276: One of the most versatile and widely used grades, C-276 provides broad resistance to a wide range of severe chemical environments, including strong oxidizers and reducing agents. It is commonly used in chemical processing, pollution control, and nuclear industries.

- Hastelloy C-22: Known for its superior resistance to oxidizing aqueous media such as chlorides and nitric acid. It also offers excellent resistance to pitting, crevice corrosion, and stress corrosion cracking.

Related Questions:

- What are the benefits of Hastelloy? Hastelloy offers exceptional corrosion resistance, high-temperature performance, and the ability to withstand aggressive chemical environments.

- Where is Hastelloy used? Hastelloy is used in industries such as chemical processing, power generation, aerospace, marine engineering, and oil and gas extraction.

- Is Hastelloy a superalloy? Yes, Hastelloy is classified as a superalloy due to its superior strength and resistance to oxidation and corrosion at high temperatures.

- What is the difference between Monel and Hastelloy? Monel is a nickel-copper alloy that is more suitable for environments with basic corrosion challenges, while Hastelloy is better suited for extreme chemical and thermal environments due to its enhanced chemical composition.

2. Is Hastelloy Better Than Stainless Steel?

Corrosion Resistance: Hastelloy is widely known for its superior resistance to various forms of corrosion when compared to stainless steel. Stainless steel, particularly 316 or 304 grades, offers good resistance to general corrosion but can be susceptible to localized corrosion, such as pitting, crevice corrosion, and stress corrosion cracking in more aggressive environments, especially in chloride-containing media. Hastelloy, on the other hand, excels in resisting these forms of attack, even under harsher chemical conditions, thanks to its higher nickel and molybdenum content. This makes Hastelloy the preferred choice in industries such as chemical processing, where exposure to highly corrosive substances is frequent.

Durability and Strength: When it comes to durability, Hastelloy outperforms stainless steel in extreme environments, particularly in terms of high-temperature performance and chemical stability. Stainless steel performs well under moderate temperature conditions but starts to degrade in more severe settings, especially where both heat and corrosion are present. Hastelloy's creep resistance and ability to maintain structural integrity at higher temperatures give it a clear edge over stainless steel in these situations. This makes Hastelloy more suitable for use in high-temperature furnaces, chemical reactors, and heat exchangers.

Cost Considerations: Hastelloy is indeed more expensive than stainless steel due to its advanced composition and enhanced properties. However, the long-term benefits—including its superior longevity, resistance to wear, and ability to reduce maintenance and equipment replacement costs—often outweigh the initial investment, particularly for industries where uptime and equipment durability are crucial.

Related Questions:

- Is Hastelloy more expensive than stainless steel? Yes, Hastelloy costs more upfront, but its longevity and performance in severe conditions can make it more cost-effective over time.

- What is the strongest alloy of steel? High-strength steels like Maraging Steel or 17-4 PH Stainless Steel offer some of the highest strength-to-weight ratios, but Hastelloy has better overall durability in extreme environments.

- What is the most corrosion-resistant steel alloy? Super duplex stainless steels like 2507 offer excellent corrosion resistance, though Hastelloy often surpasses it in highly corrosive environments.

3. Hastelloy vs Inconel: Which is Better?

Performance in Extreme Environments: Both Hastelloy and Inconel are nickel-based superalloys designed to perform in extreme environments, but they excel in slightly different areas. Inconel is renowned for its excellent oxidation and high-temperature resistance, making it ideal for high-heat applications like gas turbines and jet engines. Hastelloy, while also performing well at high temperatures, shines in environments where corrosion resistance is critical, particularly against aggressive chemicals and reducing agents. For example, Hastelloy is preferred in the chemical processing industry, while Inconel is often used in aerospace and power generation.

Corrosion Resistance: Hastelloy generally offers better corrosion resistance than Inconel, particularly in reducing environments, such as those involving sulfuric acid or hydrochloric acid. Inconel, on the other hand, performs well in oxidizing conditions but is more vulnerable in reducing environments where Hastelloy excels. Depending on the specific industrial application—such as whether the environment is oxidizing or reducing—one material may be favored over the other.

Mechanical Properties: While both Hastelloy and Inconel are strong materials, Inconel tends to offer better mechanical strength at very high temperatures, maintaining its properties in applications where temperatures soar beyond 1000°C. Hastelloy is still robust in high-temperature settings, but its strength is more notable in chemical resistance rather than extreme heat. Both materials offer excellent creep resistance, though the choice between the two often depends on whether chemical resistance or heat resistance is more critical for the application.

Related Questions:

- Is Hastelloy stronger than Inconel? In terms of chemical resistance, Hastelloy can be considered stronger, especially in corrosive environments, but Inconel is typically stronger at extremely high temperatures.

- What material is harder than Inconel? Materials like tungsten or tantalum have higher hardness ratings, though these are typically used in very specialized applications.

- What are the disadvantages of Inconel? One disadvantage of Inconel is its vulnerability to reducing environments, where it can suffer corrosion, and its higher cost relative to some other materials.

4. Common Uses of Hastelloy

Industries and Applications

Hastelloy, a family of corrosion-resistant alloys, is widely used across several industries due to its exceptional resistance to high temperatures and corrosive environments. Key industries include:

- Chemical Processing: Hastelloy is crucial in environments where chemicals can cause corrosion, such as in reactors, heat exchangers, and piping systems.

- Aerospace: Used in components that must withstand extreme temperatures and pressures, such as turbine engines and exhaust systems.

- Marine Applications: Ideal for applications exposed to seawater and other harsh environments, including shipbuilding and offshore oil drilling.

Specific Components

Hastelloy is employed in various critical components, including:

- Heat Exchangers: Its resistance to oxidation and reduction makes it suitable for heat exchangers in chemical plants, ensuring efficiency and longevity.

- Pressure Vessels: Used in pressure vessels where high pressure and temperature are common, providing safety and reliability in demanding environments.

- Reactors: Essential for reactors that process corrosive chemicals, ensuring structural integrity and minimizing contamination.

Related Questions

-

What is Hastelloy used for?

Hastelloy is primarily used in applications requiring high corrosion resistance, high-temperature stability, and structural integrity, such as chemical processing, aerospace, and marine industries. -

How much does Hastelloy cost?

The cost of Hastelloy varies depending on the specific grade and market conditions, typically ranging from $30 to $50 per pound or more, reflecting its high-performance properties. -

Is Hastelloy magnetic?

Most Hastelloy alloys are non-magnetic, which is advantageous in many applications, particularly in the aerospace and medical fields where magnetic properties can be a concern.

5. Disadvantages of Hastelloy

Cost

The primary disadvantage of Hastelloy is its high cost compared to other materials. The expense is justified in applications where the performance benefits—such as corrosion resistance and high-temperature stability—are critical for safety, efficiency, and longevity.

Machinability

Machining Hastelloy can be challenging due to its toughness and work-hardening properties, which can lead to tool wear and difficulty in achieving precise dimensions. Potential solutions include:

- Using specialized cutting tools: Carbide tools with specific geometries can enhance performance.

- Optimizing machining conditions: Slower speeds and adequate cooling can help mitigate tool wear.

Other Limitations

- Potential Over-engineering: In some applications, Hastelloy may be more robust than necessary, leading to over-engineering and unnecessary costs. Other materials may suffice in less demanding environments.

Related Questions

-

What are the disadvantages of Hastelloy?

The main disadvantages include high cost, machining difficulties, and the potential for over-engineering in applications where less expensive materials could be adequate. -

Why is Hastelloy difficult to machine?

Hastelloy’s difficulty in machining is due to its toughness, work-hardening behavior, and the tendency to cause tool wear, which can complicate the machining process and increase production costs.

6. Hastelloy and Its Competition

Hastelloy vs. Monel

-

Chemical Composition:

- Hastelloy: Primarily nickel with molybdenum, chromium, and other alloying elements. Its specific composition varies by grade.

- Monel: An alloy of nickel (about 67%) and copper, often with smaller amounts of iron, manganese, carbon, and silicon.

-

Corrosion Resistance:

- Hastelloy: Exceptional resistance to a wide range of corrosive media, including oxidizing and reducing environments. It performs well in high-temperature applications.

- Monel: Highly resistant to corrosion in seawater and reducing environments but less effective against strong oxidizers.

-

Specific Industrial Applications:

- Hastelloy: Commonly used in chemical processing, aerospace applications, and nuclear reactors due to its high-temperature resistance and durability.

- Monel: Widely used in marine applications, oil and gas, and chemical processing where resistance to seawater and reducing conditions is essential.

Hastelloy vs. Titanium

-

Weight:

- Hastelloy: Denser than titanium, making it heavier for equivalent applications.

- Titanium: Known for its high strength-to-weight ratio, making it lighter, which is particularly advantageous in aerospace applications.

-

Corrosion Resistance:

- Hastelloy: Offers superior corrosion resistance in a broader range of corrosive environments, including those involving chlorides and acids.

- Titanium: Excellent resistance to most corrosive environments, especially in alkaline conditions and seawater, but may not perform as well in highly reducing conditions compared to Hastelloy.

-

Cost:

- Hastelloy: Generally more expensive than titanium, due to its more complex alloying elements and processing requirements.

- Titanium: While still costly, titanium can be more economical in certain applications due to its lighter weight and the decreasing costs of production over time.

Related Questions

-

Is Hastelloy better than Monel?

It depends on the application. Hastelloy offers superior performance in more aggressive corrosive environments, while Monel is effective in less severe conditions, especially in seawater. -

Is Hastelloy better than Inconel?

Hastelloy and Inconel are both high-performance alloys, but Hastelloy is generally favored for its superior resistance to corrosion and high temperatures in chemical processing applications, while Inconel is often used in high-temperature environments like gas turbines.

7. Other Names and Variations of Hastelloy

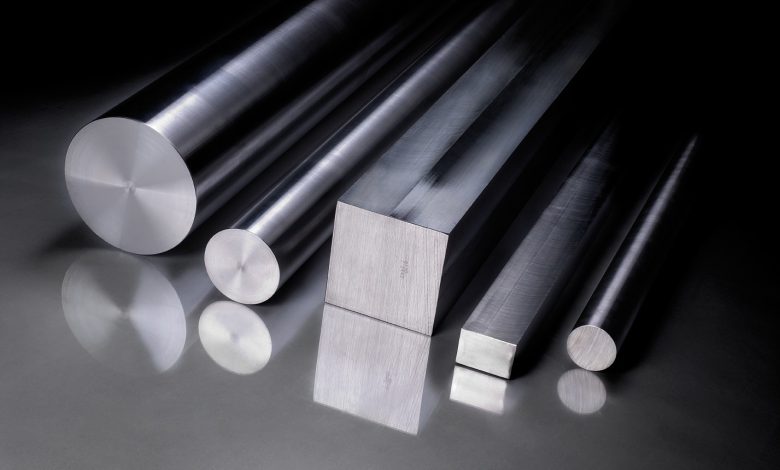

Alternative Names and Forms

Hastelloy is primarily known by its brand name; however, it may also be referred to by specific grades (e.g., Hastelloy C-276, C-22) in different regions or industries. There are variations based on application requirements and specific compositions.

Grades and Specifications

Several grades of Hastelloy are designed for different properties and applications:

- Hastelloy C-276: Excellent resistance to pitting, stress corrosion cracking, and oxidizing atmospheres; widely used in chemical processing and pollution control.

- Hastelloy B-3: Optimized for use in reducing environments, such as hydrochloric acid and sulfuric acid processing.

- Hastelloy X: Known for high-temperature strength and oxidation resistance, commonly used in aerospace applications and industrial furnaces.

Related Questions

-

Is Hastelloy a type of steel?

No, Hastelloy is not a type of steel; it is a nickel-based alloy known for its high corrosion resistance and high-temperature stability. -

How to identify Hastelloy?

Identification can be achieved through:- Material Testing: Using chemical analysis to determine the alloying elements.

- Manufacturer’s Certification: Documentation from the manufacturer confirming the material's specifications.

- Visual Inspection: Hastelloy typically has a distinct surface finish compared to other metals, but visual inspection alone may not be sufficient.

.jpg)

8. Conclusion

Recap of Hastelloy's Key Strengths

Hastelloy remains a top choice in high-performance environments for several compelling reasons:

-

Corrosion Resistance: Its exceptional ability to withstand aggressive corrosive environments makes it ideal for applications in chemical processing, aerospace, and marine industries. Hastelloy’s formulations are specifically engineered to resist a wide range of chemicals, including acids and salts, providing reliability where other materials might fail.

-

Durability: Known for its strength and durability, Hastelloy maintains its integrity under extreme conditions, including high temperatures and pressures. This durability ensures long-lasting performance and reduces the need for frequent replacements, ultimately leading to cost savings over time.

-

Versatility: The wide range of Hastelloy grades allows for its application across various industries and environments. From reactors and heat exchangers in the chemical industry to components in aerospace and marine settings, Hastelloy adapts to meet diverse engineering requirements.

Future Trends

The future of Hastelloy looks promising, with emerging uses in several key areas:

-

Renewable Energy: As the world shifts towards sustainable energy solutions, Hastelloy is finding applications in energy sectors such as wind and solar power. Its corrosion resistance makes it suitable for components in harsh environmental conditions, including offshore wind turbines.

-

High-Tech Industries: The demand for advanced materials in sectors such as electronics and semiconductor manufacturing is growing. Hastelloy’s properties can enhance the performance of components that require high precision and durability under varying environmental conditions.

-

Advanced Engineering Applications: As engineering challenges evolve, Hastelloy will continue to play a crucial role in developing innovative solutions, particularly in high-performance and high-temperature applications. Its ability to be fabricated into complex shapes and components positions it well for future technological advancements.

In summary, Hastelloy's unique combination of corrosion resistance, durability, and versatility makes it an invaluable material in various high-performance environments. Its adaptability ensures that it will continue to meet the demands of emerging industries and applications, solidifying its role as a leading material in advanced engineering.

Get Quote

- Visit our website: https://www.nbyichou.com/

- Email us: [email protected]

- Call us/whatsapp: +86 13355741031

- Chat with us: Live chat support available on our website