If you're looking to learn about injection mold plastics, you've come to the right place. In this comprehensive guide, we'll take you through everything you need to know about this versatile manufacturing process that has revolutionized the production of plastic components. Whether you're a student studying engineering, a professional working in the field, or simply curious about the world of plastics, this guide will provide you with a solid foundation. From the basics of injection molding to the different types of plastics used in the process, we'll cover it all. You'll gain insights into the various stages of injection molding, including design considerations, mold fabrication, and the actual injection process. We'll also explore the key properties and characteristics of popular injection mold plastics, such as polypropylene, polystyrene, and polyethylene. So get ready to dive into the fascinating world of injection mold plastics. By the end of this guide, you'll have a thorough understanding of the process and be equipped with the knowledge to make informed decisions for your own projects. Let's get started!

How Injection Molding Works

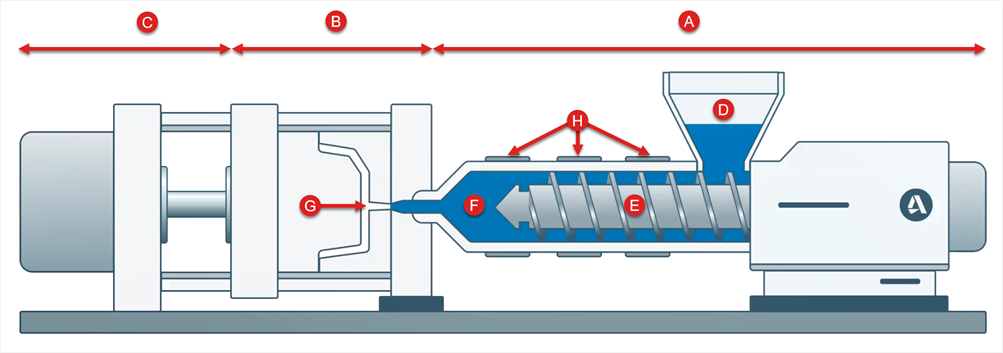

Injection molding is a precision process that involves injecting molten plastic material into a mold cavity under high pressure. The mold, usually made from steel or aluminum, is carefully designed to shape the plastic as it cools and solidifies. Once the part is set, it's ejected from the mold, ready for use. This highly automated process ensures efficient production and consistent product quality.

Types of Injection Mold Plastics

The choice of plastic material is pivotal in injection molding. Different plastics offer distinct characteristics that determine the final product's properties. Thermoplastics like polyethylene, polypropylene, and ABS are popular choices due to their versatility, durability, and ease of processing. Thermosetting plastics, such as epoxy and phenolic resins, offer excellent heat resistance and dimensional stability. The selection depends on factors like mechanical requirements, environmental conditions, and regulatory standards.

Properties of Injection Mold Plastics

Injection mold plastics boast a wide spectrum of properties. They can exhibit exceptional strength, impact resistance, flexibility, transparency, and more. The choice of material allows manufacturers to fine-tune attributes to match specific application needs. For instance, medical devices require biocompatible materials, while automotive components demand a balance between strength and weight.

.jpg) Common Applications of Injection Mold Plastics

Common Applications of Injection Mold Plastics

The ubiquity of injection mold plastics is evident across industries. From consumer goods like toys, bottles, and electronics to intricate medical devices, automotive parts, and aerospace components – injection molding's adaptability shines through. The process's ability to produce complex shapes with precision has led to its application in crafting everything from tiny gears to large plastic panels.

Advantages of Using Injection Mold Plastics

The advantages of injection molding plastics are multifaceted. Speedy production, high repeatability, and minimal material wastage make it a cost-effective option. The process accommodates intricate designs and allows for efficient integration of features. Moreover, the excellent surface finish straight out of the mold often eliminates the need for additional finishing steps.

Challenges and Limitations of Injection Mold Plastics

While injection molding is a versatile technique, it's not without challenges. Design intricacies can lead to non-uniform cooling, resulting in defects like warping and sink marks. Material selection requires a deep understanding of compatibility, as some plastics can degrade during processing. Initial tooling costs can be significant, which necessitates careful consideration for low-volume production runs.

Best Practices for Working with Injection Mold Plastics

To maximize the benefits of injection molding, adhering to best practices is crucial. Collaborative design efforts that consider moldability early in the process can prevent issues down the line. Proper gating and venting strategies ensure uniform filling and prevent air traps. Optimizing process parameters like temperature, pressure, and cooling time can significantly enhance part quality and reduce cycle times.

Trends and Innovations in Injection Mold Plastics

The injection mold plastics landscape continues to evolve, driven by technological innovations. Advanced simulation software enables more accurate predictions of part behavior, aiding in design optimization. The integration of Industry 4.0 principles, such as IoT-enabled sensors on molds, enhances process monitoring and real-time adjustments. Sustainable materials and practices also play a vital role, addressing environmental concerns.

Conclusion: Choosing the Right Injection Mold Plastics for Your Project

Conclusion: Choosing the Right Injection Mold Plastics for Your Project

In the dynamic realm of injection mold plastics, success lies in making well-informed decisions. Consider the specific requirements of your project – mechanical, aesthetic, regulatory – and choose the plastic material that aligns with your objectives. Collaborate closely with experts in injection molding and leverage cutting-edge technologies to refine your designs and streamline production. By embracing the versatility, precision, and innovation that injection molding offers, you're poised to unlock endless possibilities and pave the way for a future molded in plastic excellence.

.jpg)

At YICHOU, we pride ourselves on being a pioneering Chinese component manufacturing factory, specializing in cutting-edge plastic mold production. Here are some frequently asked questions about our innovative approach:

1. What is YICHOU's expertise in Injection Mold Plastics?

At YICHOU, we're a leading Chinese manufacturing factory with a wealth of experience in Injection Mold Plastics. Our state-of-the-art facilities, combined with a team of experts, enable us to offer cutting-edge solutions for a diverse range of industries. Whether it's intricate medical devices or robust automotive components, our expertise ensures top-notch quality and precision.

2. Which Injection Mold Plastics does YICHOU specialize in?

YICHOU specializes in a wide array of Injection Mold Plastics, including thermoplastics like polyethylene, polypropylene, and ABS, as well as advanced materials like thermosetting plastics. Our in-depth knowledge of these materials allows us to tailor solutions to meet your project's specific requirements, whether it's exceptional strength, flexibility, or transparency.

3. What are the Advantages of Choosing YICHOU for Injection Mold Plastics?

Opting for YICHOU comes with a host of advantages. Our streamlined injection molding process ensures rapid production, while our stringent quality control guarantees consistency and reliability. We offer a comprehensive suite of services, from collaborative design optimization to efficient production runs. With YICHOU, you're not just choosing a manufacturer – you're choosing a partner committed to your success.

4. How Does YICHOU Address Challenges in Injection Mold Plastics?

Challenges in Injection Mold Plastics are met head-on by YICHOU's dedicated team. Our experience allows us to identify potential design issues early, minimizing defects like warping and sink marks. We meticulously select materials to prevent degradation during processing. By collaborating closely with us, you can navigate challenges and arrive at innovative solutions that optimize your project's outcome.

5. What Sets YICHOU Apart in the Injection Mold Plastics Industry?

YICHOU stands out in the Injection Mold Plastics industry due to our unwavering commitment to innovation and excellence. We embrace the latest trends and technologies, ensuring that your projects benefit from advanced simulation software and Industry 4.0 principles. Our sustainable practices underline our responsibility towards the environment and the future. When you choose YICHOU, you're choosing a partner that's dedicated to shaping the future of injection molding.

Experience the power of precision, innovation, and collaboration with YICHOU's Injection Mold Plastics. Contact us today to embark on a journey that transforms your concepts into reality.

GET QUOTE

- Visit our website: https://www.nbyichou.com/

- Email us: [email protected]

- Call us/whatsapp: +86 13355741031

- Chat with us: Live chat support available on our website