Are you looking to improve your lathe skills and achieve precision and efficiency in your work? Look no more! In this comprehensive guide, we'll unlock the secrets of lathe processing, giving you the knowledge and techniques you need to take your craft to the next level.

Whether you're an experienced mechanic or just beginning your journey, understanding the intricacies of lathe tools is crucial to producing high-quality, accurate results. With the right tools and techniques, you can create precise cuts, and smooth finishes, and maximize your workshop efficiency. From choosing the right tool material to optimizing tool geometry and choosing the right cutting speed, this guide covers everything. We'll delve into the fundamentals of lathe processing, explore advanced techniques, and share expert tips to help you get the best results.

So whether you're working on metal, wood, or any other material, be prepared to unlock the secrets of lathe tools and take your craft to new heights. Let us gain insight into and unlock the full potential of your lathe.

1. The importance of precision and efficiency in lathe operation

In the field of machining, lathe operation is a crucial process, and its accuracy and efficiency are directly related to product quality and production costs. The importance of precision in lathe operation cannot be ignored because it directly affects the size, shape, and surface quality of the parts. In the manufacturing industry, many components require high precision, such as aerospace, automotive manufacturing, and medical devices, and any small size deviation can lead to product failure or performance degradation.

In addition, accuracy is closely related to the assembly and interchangeability of the product. If parts do not conform precisely to the design requirements, the assembly process of the entire product may be affected, resulting in production line stagnation and unnecessary cost increases. Therefore, in lathe operation, ensuring a high degree of precision machining is one of the key factors to ensure product quality and the smooth running of the overall manufacturing process.

At the same time, efficiency is equally important in lathe operation. Efficient processing can greatly improve production capacity, reduce production costs, and shorten product time to market. In the modern manufacturing environment, the market demand for fast delivery and high production capacity is increasing, so the efficiency of lathe operation is a core goal pursued by manufacturing companies. By using advanced processing technology, intelligent production equipment, and optimized process flow, the efficiency of lathe operation can be effectively improved, making enterprises more competitive in the fierce market competition.

Overall, precision and efficiency in lathe operation are complementary, and together they shape the face of modern manufacturing. Precision is the cornerstone of product quality and reliability, and efficiency is an important guarantee for the competitiveness survival, and development of enterprises. While pursuing high quality and high efficiency, the manufacturing industry needs to constantly introduce innovative technologies and processes to adapt to the constant changes in the market and achieve sustainable development.

2. Lathe tool type

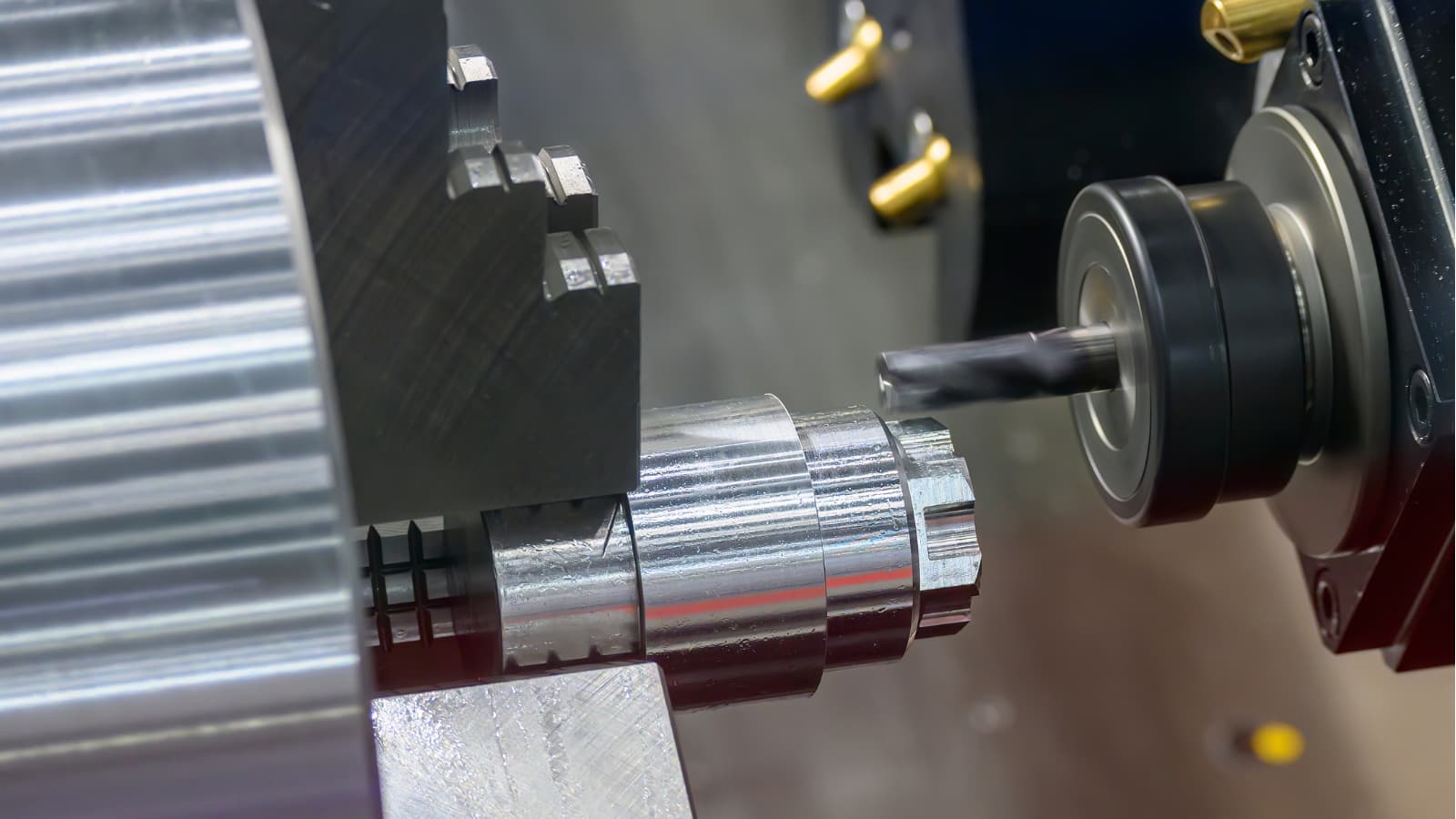

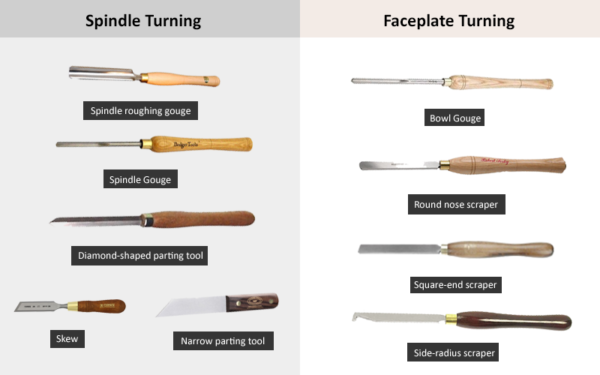

A lathe is a common metalworking machine tool used to cut, grind, drill, and shape machining materials by rotating the workpiece as well as a tool in relative motion. In lathe operation, different workpieces and machining requirements require the use of various types of lathe tools. Here are some common lathe tool types:

Turning tool: Turning tool is the main tool used to cut the workpiece on the lathe. It can be divided into outer round turning tools and inner hole turning tools, according to the cutting position and direction to choose. Turning tools are usually made of cemented carbide or high-speed steel to ensure their rigidity and wear resistance.

Drill: A tool used to drill holes in the workpiece. The shape and size of the bit can be selected according to the desired aperture and depth.

Milling cutters: Milling cutters on lathes are used for plane, profile, and surface machining. Milling cutters of different shapes and blade numbers can be used to fulfill various machining requirements.

Gear shaper cutter: used for machining gear and other tooth-shaped parts. The gear shaper is usually selected according to the module and number of teeth of the gear.

Tapping knife: used to cut threads on the workpiece. The tapping tool can be used for machining internal and external threads.

Grinding machine: A process for achieving higher precision and surface quality through grinding operations. On lathes, grinders are usually used for fine machining of special workpieces.

Planer knife: used for plane planing, usually used for surface treatment of large workpieces.

Cutting knife: used to cut the workpiece, usually used for intercepting and sizing processing.

The choice of these lathe tools depends on the shape, size, material of the workpiece, and the required machining accuracy. In actual production, the operator needs to reasonably select and use these tools according to specific needs to ensure the efficiency and accuracy of the processing process.

3. Select the right lathe tool for the specific task

Choosing the right lathe tool is crucial for a specific task, which directly affects machining efficiency, workpiece quality, and the cost of the process. Here are some common lathe tool selection guidelines to meet the needs of a specific task:

Turning tool selection:

Outer turning tool: used for roughing and finishing the outer profile.

Inner hole turning tool: used for machining the Inner profile of the hole to ensure the size and surface quality of the inner hole.

Bit selection:

Conventional drill bit: suitable for the processing of general holes.

Center bit: Used for positioning and pre-hole.

Special shape drill bits: Used for machining holes of complex shapes.

Milling cutter selection:

End milling cutter: suitable for surface machining.

Ball end milling cutter: used for surface machining.

T-milling cutter: used for machining T-slots.

Gear shaper tool selection:

Modular gear shaper: selected according to the module of the gear, used for gear machining.

Trim gear shaper: Used for trim and root machining.

Tapping tool selection:

Internal tapping tool: used for machining internal threads.

External tapping knife: used for processing external threads.

Grinding machine selection:

Surface grinding machine: used for surface processing to improve surface smoothness.

Cylindrical grinding machine: Used for external and internal grinding of axial parts.

Planer knife selection:

Roughing planer knife: used to remove large amounts of material.

Finishing planer knife: Used to improve surface finish.

Cutting tool selection:

Cutting blade: Select the appropriate blade according to the workpiece material and size.

When choosing a tool, it is necessary to consider the material, shape, size of the workpiece, and the required machining accuracy. In addition, understanding the tool materials, coatings, and tool geometry of different tools is also key to making an informed choice. Ultimately, by combining these factors, it is possible to optimize lathe operation, increase production efficiency, and ensure the quality of the final product.

4. Proper maintenance and maintenance of lathe tools

The proper maintenance and maintenance of lathe tools is essential to ensure the normal operation of the machine, extend the life of the tool, and improve the machining accuracy. Here are some suggestions to help you maintain and maintain your lathe tools:

Regular cleaning: Clean lathes and tools regularly to remove chips, cutting fluids, and other impurities. Clean with a suitable cleaner and brush to ensure that all components are kept clean.

Lubrication system: Ensure the normal operation of the lubrication system of the lathe. Regularly check the quality of the lubricating oil and the lubrication of the lubrication point, and add or replace the lubricating oil as needed.

Regular inspection of tools:

Check the wear degree of the tool, and replace the seriously worn tool in time.

Use a microscope or measuring instrument to check the condition of the tool edge and ensure that the size and shape of the tool meet the requirements.

Tool storage: Properly store tools when not in use to prevent tool damage. Use a suitable tool bin or tool cabinet and avoid collision between tools.

Cutting fluid management: For lathes that use cutting fluid, check the cleanliness and concentration of cutting fluid regularly. Ensure that there is no excessive cutting residue and bacteria in the cutting fluid.

Check the geometric accuracy of the machine tool: check the geometric accuracy of the machine tool regularly, including the detection of the guide rail, threaded rod, slider, and other parts to ensure its accuracy and flatness.

Regular calibration: The machine tool is calibrated regularly to ensure its working accuracy. In particular, CNC lathes need to regularly check and correct the parameters of the CNC system.

Safety precautions: Follow the correct safe operation procedures, ensure that the operator is familiar with the safety requirements of the machine, and use appropriate personal protective equipment.

Fastener inspection: Regularly check various fasteners on the lathe, including screws, nuts, couplings, etc., to ensure their tightness and prevent tool deviation or machine instability caused by loosening.

Record maintenance log: Record maintenance and maintenance dates, contents, and problems found. This helps establish a maintenance plan, identify potential problems, and take action promptly.

Through regular maintenance and maintenance, you can maximize the service life of lathe tools, improve production efficiency, and ensure processing accuracy and product quality.

5. Tips for achieving precision in lathe operation

Achieving high-precision machining in lathe operation is key, here are some tips and considerations to help improve the accuracy of lathe operation:

Process planning and preparation: Before the operation, carefully develop the process plan, including the selection of appropriate tools, cutting parameters, and machining sequence. Ensure that the workpiece is firmly held and that the machine geometry is in good condition.

Tool selection and grinding: Use high-quality tools and ensure that their size, shape, and cutting-edge quality meet requirements. Check and grind tools regularly to avoid using tools that wear too much.

Appropriate cutting speed and feed rate: According to the workpiece material, tool material, and processing requirements, select the appropriate cutting speed and feed rate. Too high or too low cutting speed may affect the machining accuracy.

Regular measurement and calibration: The workpiece is regularly measured with the appropriate measuring tools to ensure that the machining results meet the specifications. Perform regular calibration of the machine when required.

Temperature control: Avoid excessive temperature on the machine and the workpiece. The temperature change may lead to the expansion and contraction of the machine tool structure, which in turn affects the machining accuracy. Select the appropriate cutting fluid and cooling system to ensure the stability of temperature during the cutting process.

Reduce vibration and shock: Reduce the impact of machine and workpiece vibration on machining accuracy. Use suitable clamping and supporting devices to avoid impact loads, especially during high-speed machining.

Selection of cutting methods: In some machining processes requiring high precision, consider using non-traditional cutting methods such as grinding to obtain higher surface quality and accuracy.

Optimization of cutting profile: Optimize the profile and adopt appropriate cutting paths and tool tracks to reduce cutting force and improve machining accuracy.

Tool wear monitoring: Use a tool wear monitoring system to detect and replace worn tools in time to maintain the consistency and stability of processing.

Staff training: Conduct professional training for operators to ensure that they understand and correctly execute the process requirements, are familiar with the operating procedures of the machine, and can identify and respond to possible problems during the processing.

By combining these techniques and considerations, you can improve the accuracy of lathe operation, ensure that the machining results meet the design requirements, and provide a reliable basis for the production of high-quality parts.

6. Strategies to improve the efficiency of lathe operation

Improving the efficiency of lathe operations is one of the goals pursued in the manufacturing industry, and here are some strategies that can help optimize lathe operations and increase productivity:

Advanced numerical control technology: The introduction of advanced numerical control (CNC) technology, through programming to achieve automatic control, and improve machining accuracy and efficiency. Optimize cutting paths and tool paths with CNC programming software to reduce non-productive time.

Automatic tool change system: Install an automatic tool change system to reduce tool change time and improve production continuity. The automatic tool-changing system enables the use of multiple tools on the same workpiece, reducing downtime.

Fast fixture and workpiece changing: Reduce clamping and changing time with fast fixture and workpiece changing equipment. This can improve production efficiency without affecting machining accuracy.

High-speed cutting technology: The application of high-speed cutting technology, including increasing the cutting speed and feed rate, to reduce the processing cycle. At the same time, the appropriate cutting tools and cooling systems are selected to ensure high-speed cutting while maintaining machining quality.

Online inspection system: The use of an online inspection system to monitor the processing process, timely detection and correction of problems, and reduce the rate of scrap. This helps to improve the first pass rate and avoid the waste of time in repeated processing and grinding.

Process parallelization: Possible parallel processes are organized to reduce waiting time. At the same time, the production process is optimized to reduce non-value-adding processes.

Predictive maintenance: Establish a predictive maintenance system to reduce unplanned downtime by monitoring machine conditions and tool wear to predict potential failures in advance.

Training and skill development: Provide staff training to improve their operational and programming skills. Skilled operators can utilize machine tools more efficiently and quickly adapt to new processes and technologies.

Resource optimization: Ensure full utilization of machine tools and tools to avoid unnecessary idling and waiting time. Rational planning of production scheduling, so that the lathe is always in an efficient operation state.

Data analysis and continuous improvement: Collect and analyze production data to identify potential bottlenecks and optimization points. Adopt a continuous improvement approach to continuously optimize production processes and lathe operation strategies.

Through the comprehensive application of these strategies, manufacturing enterprises can improve the efficiency of lathe operation, reduce production costs, improve product quality, and thus maintain competitiveness in the market competition.

7. Common errors that should be avoided in lathe processing

In lathe machining, it is crucial to avoid some common mistakes, which help ensure workpiece quality, increase production efficiency, and extend the life of machine tools and tools. Here are some common mistakes to avoid:

Unreasonable cutting parameters: Setting unreasonable cutting speed, feed rate, and cutting depth can lead to increased tool wear, reduced workpiece surface quality, and excessive machine load. The cutting parameters should be adjusted according to the workpiece material and requirements.

Ignore tool wear: not timely replacement of severely worn tools will affect the machining accuracy and surface quality. Check and replace tools regularly and adopt reasonable tool management strategies.

Clamping is not firm: Incorrect workpiece clamping can lead to workpiece displacement, vibration, and machining deviation. Ensure that the clamping device is firm and reliable, and meets the clamping requirements of the workpiece.

Unreasonable process planning: No reasonable process planning may lead to improper processes and increase the production cycle. Develop a reasonable process plan, including cutting sequence and tool selection.

Ignoring cutting fluid management: The quality and use of cutting fluid are critical to the process. Unreasonable use of cutting fluid may lead to premature tool wear and workpiece surface quality degradation.

Inadequate operator skills: Operator lack of necessary skills and training can lead to misoperation, machine damage, or uneven machining quality. Regular training to improve the technical level of operators.

Unreasonable cutting path: Improper cutting path selection can lead to excessive wear of tools and machine tools, as well as a decline in workpiece surface quality. Use a reasonable cutting path to avoid unnecessary cutting and machine load.

Neglect of regular maintenance: Failure to perform regular maintenance can lead to wear, loss of accuracy, and failure of machine parts. Establish a regular maintenance schedule to ensure the machine stays in top working condition.

Neglect of workpiece and tool matching: not selecting the appropriate tool and tool material can lead to reduced cutting quality and shortened tool life. Select tools and tool coatings that match the workpiece material.

Unreasonable cooling and lubrication: Not providing adequate cooling and lubrication during the cutting process can lead to overheating of the tool, deformation of the workpiece, and a decline in surface quality. Ensure proper cooling and lubrication systems are used during cutting.

By avoiding these common errors, you can improve the stability, efficiency, and quality of lathe processing, reduce production costs, and extend the life of your machine and tools.

8. Advanced technology of lathe processing

The field of lathe machining is constantly evolving, with a range of advanced technologies emerging to improve production efficiency, machining accuracy, and flexibility. The following are some advanced technologies for lathe processing:

Numerical Control Technology (CNC): CNC lathes use computer numerical control systems to control the movement of tools and workpieces through pre-programmed instructions. This technology provides a high degree of automation and precision, making the process more flexible, fast, and capable of producing complex parts.

Five-axis machining: The five-axis lathe can move in five-coordinate directions, allowing multi-direction, and multi-angle cutting of the workpiece. This flexibility makes it easier to process complex surfaces and improves the precision and efficiency of processing.

High-speed cutting (HSC): High-speed cutting technology utilizes high-speed rotating tools with higher cutting speeds and smaller feed rates to increase production efficiency, reduce thermal impact, and improve surface quality.

High-speed milling (HSM): High-speed milling is a technology focused on improving milling efficiency, reducing production cycles, increasing cutting efficiency, and improving surface quality through high-speed rotating tools and higher cutting speeds.

Tool coating technology: Advanced tool coating technology, such as TiAlN, TiCN, etc., improves the wear resistance and high-temperature resistance of the tool, extends the tool life, and reduces the number of tool changes, thereby improving production efficiency.

Intelligent manufacturing and Industry 4.0: The use of the Internet of Things, big data, artificial intelligence, and other technologies to achieve the interconnection of lathe equipment, optimize production processes through data analysis, and realize intelligent manufacturing.

Ultrasonic machining: Ultrasonic machining uses ultrasonic vibration to cut, grind, or weld materials, which is suitable for hard and brittle materials, and can improve processing accuracy and reduce processing deformation.

Advanced cutting materials: The use of advanced tool materials, such as cubic boron nitride (CBN) and polycrystalline diamond (PCD), to improve the hardness and wear resistance of the tool, suitable for the processing of high hardness, high wear resistance materials.

Processing simulation technology: The use of processing simulation software, in advance to simulate the processing process, optimize the cutting path, avoid collision, and improve processing safety and efficiency.

Optical measurement technology: The use of high-precision optical measuring equipment, such as a laser measuring instrument, optical interferometer, etc., to accurately measure the workpiece to ensure processing accuracy.

The introduction of these advanced technologies makes lathe processing more intelligent, efficient, and precise and helps to meet the needs of the modern manufacturing industry for high quality and high efficiency.

Conclusion: Using lathe tools to maximize productivity and quality

Through detailed process planning, the application of advanced technologies, and comprehensive production optimization strategies, the use of lathe tools can achieve significant productivity gains and quality optimization in the manufacturing industry. Key factors include:

Technology integration and automation: Through the integration of advanced CNC technology, high-speed cutting, five-axis machining, and other automation technologies, to achieve a high degree of flexibility and precision lathe operation, to provide efficient production solutions for target customers.

Excellent tool selection and maintenance: Professional tool selection, regular tool inspection, grinding, and replacement help ensure the reliability and high quality of the machining. This means fewer production interruptions and higher cutting efficiency for target customers.

Process optimization: Through well-designed process planning and process optimization, reduce non-production time, improve production continuity, and enhance customer processing efficiency.

Training and skill upgrading: By providing professional training to operators to ensure that they have a high level of operating and programming skills, thereby increasing the technical content of lathe operation, further ensuring that the target customers receive products with high precision machining.

Regular maintenance and maintenance: Implement a regular machine maintenance plan to ensure that all parts of the machine are always in optimal working condition. This helps reduce the risk of mechanical failure and increases the reliability of production.

Efficient quality management: The introduction of an advanced quality management system, through real-time monitoring and data analysis, maximizes the consistency and conformity of products, reduces the rejection rate, and provides more reliable products for target customers.

Continuous improvement and innovation: Encourage continuous improvement in the team and promote an innovative culture. The constant search for ways to optimize processes, and improve efficiency and quality ensures that target customers always benefit from the most advanced production processes.

Through these specialized measures, lathe operation can not only improve production efficiency and quality, but also meet the needs of target customers for high-quality and efficient products, enhance the competitiveness of enterprises, and ultimately achieve customer satisfaction and conversion transactions.

GET QUOTE

- Visit our website: https://www.nbyichou.com/

- Email us: [email protected]

- Call us/WhatsApp: +86 13355741031

- Chat with us: Live chat support available on our website