Introduction

Injection molding is a widely utilized manufacturing process that involves injecting molten material into a mold to create parts and products. It is renowned for its efficiency, precision, and ability to produce complex shapes with high consistency. This process is essential across various industries, including automotive, consumer electronics, medical devices, packaging, and more. The versatility and scalability of injection molding make it the go-to solution for mass production, enabling businesses to create high-quality parts at competitive prices.

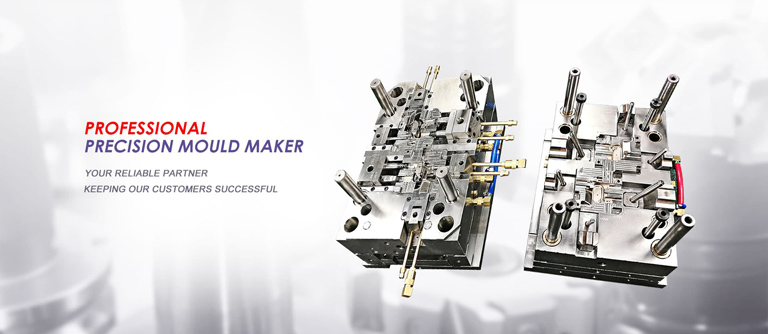

At YICHOU, we specialize in providing high-quality injection molds tailored to meet the specific needs of our clients. With years of experience in the industry, we have the expertise to deliver reliable and durable molds that are ideal for a wide range of applications. Whether you require molds for high-volume production or intricate, custom-designed parts, we are committed to helping you achieve cost-effective, precision-engineered solutions.

What is Injection Molding?

Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold under high pressure. The material is typically plastic, but metals, ceramics, and other materials can also be used. The mold, which is a hollow cavity of the desired part shape, cools and solidifies the material to form the final product.

This process is widely used for creating both simple and complex parts with a high degree of accuracy. Once the mold is made, injection molding allows for rapid mass production of identical parts, making it one of the most efficient methods for manufacturing.

Benefits of Injection Molding:

- Precision: Injection molding offers high levels of precision, producing parts with tight tolerances and intricate designs.

- Cost-Efficiency for Mass Production: The ability to produce large quantities at a low per-part cost makes it ideal for high-volume production. Once the mold is created, each subsequent part costs only a fraction of the original mold cost.

- Versatility: Injection molding is adaptable for a wide variety of applications, from simple consumer goods to highly specialized components used in industries such as aerospace, automotive, and medical devices.

- Consistency: The process ensures that each part is nearly identical, providing excellent consistency in product quality.

- Durability: The material selection and mold design ensure that parts produced by injection molding are strong, durable, and long-lasting.

Why Choose YICHOU for Injection Molds?

At YICHOU, we are committed to delivering top-tier injection molding services. Here’s why we stand out as a trusted partner for your molding needs:

-

Experience: With years of experience in the injection molding industry, YICHOU has a proven track record of delivering high-quality, reliable molds for a wide variety of industries, including automotive, medical, electronics, and consumer products.

-

Capabilities: We offer comprehensive solutions, from mold design and prototyping to full-scale production. Our advanced equipment and skilled team enable us to create both simple and complex molds with precision and efficiency.

-

Expertise: Our team of engineers and technicians brings extensive expertise to every project. Whether you're designing a new product or optimizing an existing one, we provide guidance and support throughout the entire process, ensuring the best results.

-

High-Quality Materials: At YICHOU, we only use the highest quality materials for our molds, ensuring durability, reliability, and long-lasting performance. Whether your project requires standard plastics or high-performance engineering materials, we have the expertise to meet your needs.

-

Quick Turnaround: We understand the importance of time in production schedules. Our efficient workflow allows us to deliver high-quality injection molds with quick turnaround times, helping you meet deadlines and get to market faster.

-

Customized Solutions: Every project is unique, and we provide tailored solutions to meet the specific requirements of your product. From custom mold designs to flexible production schedules, we ensure that your needs are met at every step of the process.

Partner with YICHOU for cost-effective, high-quality injection molds designed to enhance your product’s performance and reduce production costs.

4o

您说:

How Much Does an Injection Mold Cost? Discuss the factors that influence mold pricing, such as complexity, material type, and size. Link to specific services or case studies to showcase your pricing strategy. How to Calculate Injection Mold Costs Outline a simple formula or steps on how customers can estimate mold costs. Mention potential additional costs, such as maintenance and tooling adjustments.

ChatGPT 说:

How Much Does an Injection Mold Cost?

The cost of an injection mold can vary greatly depending on several factors. Understanding these elements is essential when considering the overall budget for a project. Here are the key factors that influence mold pricing:

-

Complexity of the Design:

- Simple designs with straightforward geometries and minimal features will generally result in a lower cost. However, complex molds with intricate geometries, undercuts, thin walls, or multiple cavities will require more advanced tooling and higher labor costs, leading to a higher price.

- Multi-cavity molds (molds that can produce several parts in one cycle) can also increase the cost, but they offer cost efficiency in large-scale production by reducing cycle time.

-

Material Type:

- The choice of mold material plays a critical role in pricing. High-durability materials like hardened steel are more expensive but are ideal for high-volume production because of their longevity. Aluminum molds, on the other hand, are less expensive and often used for lower-volume runs or prototype parts, but they wear out faster.

- Plastic type also matters. Some materials require higher processing temperatures or specific mold treatments, adding to the overall mold cost.

-

Mold Size:

- Larger molds that are needed for producing larger parts or greater quantities require more material and longer processing times, which increase costs. Molds for small, simple parts tend to be less expensive compared to molds for large, detailed components.

-

Lead Time:

- The timeframe required to produce the mold can also impact the cost. Tight deadlines may necessitate faster production, which could involve higher costs due to expedited processes, additional shifts, or outsourcing certain tasks.

-

Maintenance and Tooling Adjustments:

- Molds may require maintenance and tooling adjustments during their lifespan, particularly for high-volume production. These costs should be considered when estimating the total mold investment.

Link to YICHOU’s Services:

At YICHOU, we offer transparent pricing tailored to your specific project requirements. We understand that mold cost can be a significant investment, which is why we work with you to optimize design, material selection, and production methods to ensure cost efficiency without compromising on quality. Contact us today to get a personalized quote and see how we can help reduce your overall production costs.

How to Calculate Injection Mold Costs

Estimating the cost of an injection mold involves evaluating several factors, which can be broken down into a simple formula. Here’s a step-by-step guide on how customers can calculate their mold costs:

1. Mold Design and Manufacturing Costs:

- Design Complexity: The more intricate the part design, the more expensive the mold. This includes features like undercuts, tight tolerances, or multi-cavity designs.

- Mold Material: Choose between materials like steel, aluminum, or others based on production volume and part requirements. Steel molds are more expensive but last longer than aluminum.

2. Production Costs:

- Material Costs: The cost of the plastic or other materials used in the injection molding process.

- Machine Hourly Rates: These vary depending on the type of machine used and the complexity of the mold. The larger and more complex the mold, the more it will cost per hour to run.

- Labor Costs: This includes the cost of operating and maintaining machines, setting up the mold, and inspecting the final products.

3. Additional Costs:

- Maintenance: Over time, molds may require maintenance, which includes cleaning, repairing worn-out parts, and ensuring the mold continues to produce parts at the required quality.

- Tooling Adjustments: As part designs evolve or production volumes change, tooling adjustments may be necessary to maintain mold performance and part quality.

4. Per-Part Cost:

Once you have an estimate for the total mold and production costs, you can calculate the per-part cost by dividing the total cost by the expected number of parts to be produced.

- Formula:

Per-Part Cost = (Mold Cost + Production Costs) ÷ Number of Parts Produced

For example:

- Mold Cost: $10,000

- Production Cost (material + machine time): $5,000

- Total Parts Produced: 100,000

Per-Part Cost = ($10,000 + $5,000) ÷ 100,000 = $0.15 per part

This gives you a rough idea of the cost per part based on your total mold and production expenses.

Is Injection Molding Profitable?

Injection molding can be a highly profitable manufacturing solution, especially when it comes to mass production. There are several reasons why this process is an attractive option for businesses looking to maximize their profitability:

-

Economies of Scale: Injection molding offers low per-part costs for high-volume production. While the initial investment in mold creation and machinery may be high, the cost per part decreases significantly as production volume increases. This makes it an ideal process for businesses that need to produce large quantities of identical parts, such as in the automotive, consumer goods, and electronics industries.

-

Efficiency and Speed: The injection molding process is highly automated, allowing for fast production cycles. This means that parts can be manufactured quickly, helping companies meet tight deadlines while keeping labor costs low. The ability to produce thousands or even millions of parts in a short time frame leads to high output and maximized profits.

-

Minimal Waste: Injection molding is an efficient process that uses very little material waste compared to other manufacturing methods. The material is injected into the mold, and the leftover material can often be recycled, leading to a more cost-effective and environmentally friendly production method.

-

Consistency: Once the mold is created, the process produces parts that are highly consistent in terms of quality and shape. This low defect rate helps reduce the costs associated with rework, repairs, and returns, which can further increase profitability for businesses.

-

Long-Term Investment: Injection molds, when made from durable materials like hardened steel, can last for millions of cycles, which means the initial investment in mold creation becomes more cost-effective over time. This longevity further enhances the profitability of the process.

In summary, injection molding is a profitable manufacturing solution for companies that require high-volume, consistent production of parts. By reducing material waste, speeding up production cycles, and leveraging economies of scale, businesses can see a strong return on their investment, especially when producing large quantities of parts.

Is Injection Molding a Good Career?

From a client's perspective, the growth of demand for efficient production systems has made injection molding a strong and stable career choice for skilled professionals in the manufacturing industry. As industries across the board, from automotive to medical devices, rely on injection molding to create high-quality, mass-produced parts, the need for skilled workers in this field continues to grow.

Here are several reasons why a career in injection molding can be a great opportunity:

-

High Demand for Skilled Workers: As businesses focus on optimizing production processes for efficiency and quality, the need for professionals who can manage, operate, and maintain injection molding machines has increased. Skilled workers, such as mold designers, machine operators, and engineers, are in high demand to ensure the smooth operation of injection molding systems.

-

Growing Industry: The manufacturing sector is continually evolving, with increasing demands for precision, speed, and cost-effectiveness. As businesses look to improve their production systems, injection molding remains a key technology for producing high volumes of parts quickly and cost-effectively. This growing reliance on injection molding translates to more job opportunities in the field.

-

Career Stability and Growth: Injection molding is widely used across industries, and the need for high-quality production will likely continue to grow. This provides professionals in the field with career stability. Additionally, with advancements in technology, there are ample opportunities for professionals to learn new skills, work with state-of-the-art equipment, and take on advanced roles in the field, further expanding career growth potential.

-

Competitive Salary: Skilled workers in the injection molding industry can often command competitive salaries due to the specialized knowledge and expertise required. The demand for professionals with experience in injection molding processes, mold design, and quality control ensures that professionals can earn a good income, with opportunities for advancement.

-

Contributions to Innovation: Working in injection molding allows professionals to contribute to the development of innovative products used in everyday life. From medical devices to electronics, injection-molded components are integral to many industries. This makes a career in injection molding fulfilling, as professionals see the tangible impact of their work on the products that shape modern society.

In conclusion, injection molding offers a promising career for those interested in the manufacturing industry. With high demand for skilled professionals, career stability, opportunities for advancement, and competitive salaries, it is a strong and rewarding choice for individuals looking to enter or advance in the field of efficient production systems.

The Life Cycle of an Injection Mold

The lifespan of an injection mold is an essential factor to consider when planning your production process. Molds are designed to endure high volumes of manufacturing, but their longevity depends on several factors, including material choice, part complexity, production volume, and maintenance practices.

Mold Lifespan:

- Durable Materials: Molds made from materials like hardened steel can last for millions of cycles, making them ideal for high-volume production. These molds are typically used when long-term, mass production is required.

- Aluminum Molds: While less expensive, aluminum molds have a shorter lifespan and are more suited for low- to mid-volume runs. They are less durable but can still perform well when maintenance is regularly carried out.

- Maintenance and Wear: Over time, molds will experience wear and tear, especially with high-volume production. The lifespan of a mold will often depend on how frequently it is maintained, how well it's stored, and the type of material used in production.

Maintenance Best Practices:

- Regular Cleaning: Ensure that molds are cleaned regularly to remove debris, dust, and material residue that could affect performance.

- Lubrication: Proper lubrication of moving parts helps prevent friction and reduces wear. This is particularly important for molds with intricate components or complex part features.

- Inspection and Adjustment: Periodic inspections should be carried out to detect any signs of wear or damage early. Adjustments or repairs should be made promptly to prevent costly downtimes or part defects.

- Cooling System Maintenance: The cooling channels within the mold need to be cleaned to avoid blockages, which could lead to overheating or inconsistent cooling of parts.

- Proper Storage: When not in use, molds should be stored in a dry, climate-controlled environment to prevent rust, corrosion, or other damage.

By following these maintenance practices, the lifespan of an injection mold can be significantly extended, improving both production efficiency and cost-effectiveness.

Key Questions About Injection Molding

Here are answers to some commonly asked questions about injection molding that can help you make informed decisions for your manufacturing needs:

What is the hourly rate for injection molding?

The hourly rate for injection molding varies based on several factors, including machine type, material used, and production requirements. On average, hourly rates can range from $50 to $200 per hour depending on the complexity of the parts, mold material, and size of the injection molding machine. Factors such as labor costs and overheads can also influence the final price.

How long does it take to create an injection mold?

The time required to create an injection mold depends on the complexity of the design and the materials used. On average:

- Simple molds may take about 2 to 4 weeks.

- Complex molds with intricate designs or multiple cavities can take 6 to 8 weeks or longer. Factors such as mold size, material selection, and the need for special tooling will also affect the overall timeline.

What is the difference between extrusion and injection molding?

Both extrusion and injection molding are processes used to form parts from materials, but they differ in their methods and applications:

- Injection Molding: Material is injected into a mold under pressure, where it cools and solidifies to form a specific shape. This process is ideal for producing detailed, high-precision parts in high volumes. It is commonly used for plastic products like automotive components, medical devices, and consumer goods.

- Extrusion: Material is pushed through a die to create a continuous shape with a uniform cross-section, such as pipes, sheets, or films. The extrusion process is typically used for longer parts or continuous products and is less suitable for complex or highly detailed parts compared to injection molding.

While both processes are used for producing molded parts, injection molding is preferred for high-precision, high-volume production of intricate and diverse parts.

Conclusion

At YICHOU, we are committed to delivering high-quality, cost-effective injection molding solutions tailored to your specific needs. With our extensive experience in mold design, manufacturing, and maintenance, we ensure that your production process is efficient, precise, and reliable. Whether you require molds for high-volume production or need a custom solution, our team works closely with you to meet your exact requirements.

Call to Action:

Ready to start your project? Contact YICHOU today for a personalized quote. Our team is here to provide you with the best injection molding solutions that will help streamline your production process and achieve cost savings. Let us help you take your manufacturing to the next level!

Get Quote

- Email us: [email protected]

- Call us/whatsapp: +86 13355741031

- Chat with us: Live chat support available on our website