In the world of manufacturing and sculpting precision, die casting has emerged as a true art form. With its ability to seamlessly create complex shapes and intricate designs, die casting has become an essential technique for various industries. But what makes die casting in the modern era so innovative and advanced? In this article, we delve into the cutting-edge advancements and innovations that have revolutionized the art of die casting. From improved materials and technologies to enhanced precision and efficiency, we explore how manufacturers are pushing the boundaries of what is possible with this technique. With an emphasis on brand voice and engaging storytelling, we bring you the latest trends, techniques, and success stories from the world of modern die casting. Take a journey through the fascinating world of sculpting precision, as we uncover the secrets behind the art of die casting and its impact on industries ranging from automotive to aerospace and beyond.

.jpg)

Evolution of Die Casting Techniques

The art of die casting has evolved over centuries, tracing its roots back to ancient civilizations like Mesopotamia and China. Early practitioners used rudimentary molds made of clay or sand to craft simple metal objects, but the technique has come a long way since then. In the modern era, die casting has undergone a remarkable transformation, thanks to technological advancements and innovative processes.

One of the most significant milestones in the evolution of die casting is the shift from manual labor to mechanized precision. In the early days, craftsmen relied on their skill and dexterity to create intricate metal pieces, often with limited consistency. However, with the advent of machinery and automation, die casting became a highly precise and reproducible art form. This not only reduced the margin for error but also opened up new possibilities for artists looking to push the boundaries of their craft.

Furthermore, the types of metals used in die casting have also evolved significantly. While early die casting predominantly employed materials like bronze and copper, modern sculptors have access to a vast array of alloys, including aluminum, zinc, and magnesium. These materials offer a wide range of properties, from enhanced strength to lightweight versatility, allowing artists to explore their creativity and achieve unparalleled levels of detail in their sculptures.

As we delve into the world of die casting sculpture, it's crucial to appreciate the rich history that has paved the way for the innovative techniques and materials we have today. The journey from ancient artisans to contemporary craftsmen demonstrates how die casting has continuously adapted to the changing times, becoming an integral part of the sculpting world.

Benefits of Die Casting in Modern Sculpture

Die casting has emerged as a game-changer in the realm of modern sculpture, offering a plethora of advantages that make it a preferred choice for artists and designers alike. One of the most prominent benefits is the unparalleled precision and detail that die casting allows. The intricate molds and advanced techniques enable sculptors to bring their visions to life with unmatched accuracy. This precision is particularly beneficial for artists who aim to create intricate, lifelike sculptures or capture the nuances of their subjects.

Another significant advantage of die casting in sculpture is its efficiency. Unlike traditional sculpting methods that require extensive time and labor, die casting can produce multiple replicas of a sculpture quickly and consistently. This efficiency is not only cost-effective but also allows artists to meet the demands of a wider audience, making their work more accessible to art enthusiasts around the world.

The versatility of die casting materials is yet another compelling reason for its prominence in modern sculpture. Whether a sculptor seeks the durability of aluminum, the aesthetic appeal of bronze, or the lightweight properties of zinc, die casting offers a wide range of options. This flexibility empowers artists to choose materials that best align with their creative vision, ensuring that their sculptures not only look stunning but also endure the test of time.

Moreover, die casting is an environmentally friendly option for sculptors concerned about sustainability. The efficient use of materials and the ability to recycle scrap metal align with the principles of eco-conscious artistry. This aspect not only appeals to environmentally conscious artists but also resonates with a growing audience of art enthusiasts who prioritize sustainability in their choices.

In summary, the benefits of die casting in modern sculpture are numerous and compelling. Precision, efficiency, versatility, and sustainability are just a few of the advantages that make die casting an invaluable tool for artists seeking to push the boundaries of their craft.

Innovations in Die Casting Technology

The world of die casting is a dynamic and ever-evolving one, with continuous advancements in technology driving the art form to new heights. Innovations in die casting technology have expanded the horizons of what is possible, enabling sculptors to create sculptures that were once thought to be beyond reach.

One of the most exciting innovations in die casting is the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software. These tools allow artists to design incredibly complex sculptures with precision and detail that was previously unattainable. CAD and CAM software also facilitate the translation of these designs into intricate molds, ensuring that every element of the sculpture is faithfully reproduced during the casting process.

Another groundbreaking development is the use of 3D printing in die casting. This technology has revolutionized the creation of molds, making the process faster and more cost-effective. 3D-printed molds can capture even the finest details of a sculpture, resulting in highly accurate and intricate castings. Additionally, 3D printing allows for greater experimentation and iteration in the design phase, as changes can be made quickly and without the need for traditional mold-making techniques.

The incorporation of robotics and automation has further elevated die casting to new levels of efficiency and consistency. Automated systems can perform tasks such as pouring molten metal, cooling, and even finishing with incredible precision. This not only reduces the risk of human error but also speeds up production, making large-scale die casting projects more feasible than ever before.

Furthermore, advancements in metallurgy have expanded the range of materials available for die casting. High-performance alloys with enhanced properties, such as superior strength or heat resistance, provide sculptors with more choices for achieving their artistic visions. These innovative materials have also contributed to the longevity and durability of die-cast sculptures.

As technology continues to evolve, it's an exciting time for artists and sculptors who utilize die casting. These innovations not only make the process more accessible but also inspire artists to push the boundaries of their creativity, resulting in truly extraordinary works of art that captivate and amaze audiences worldwide.

Advanced Materials for Precision Sculpting

In the world of die casting, the choice of materials plays a pivotal role in the creation of sculptures with exceptional precision and aesthetics. The selection of advanced materials has opened up a realm of possibilities for sculptors, enabling them to achieve intricate details, impressive durability, and unique visual effects.

One of the most sought-after materials in die casting sculpture is aluminum. This lightweight yet sturdy metal is favored for its excellent casting properties, making it ideal for artists aiming to capture intricate details and achieve a polished finish. The versatility of aluminum allows sculptors to experiment with a wide range of styles and sizes, from delicate figurines to monumental outdoor installations.

Bronze, a classic choice for sculptures throughout history, continues to be a preferred material in die casting. Its timeless appeal and ability to develop a beautiful patina over time make it a favored option for sculptors seeking a traditional yet enduring aesthetic. The use of bronze in die casting provides artists with the opportunity to create sculptures that stand the test of time both in terms of artistry and physical resilience.

For those sculptors looking to push the boundaries of their craft, magnesium offers a remarkable choice. This lightweight metal boasts exceptional strength, making it suitable for large-scale and structurally demanding sculptures. The use of magnesium in die casting opens up possibilities for innovative and bold designs that may not be achievable with other materials.

Additionally, zinc alloys have gained popularity in recent years due to their versatility and aesthetic appeal. These alloys can mimic the appearance of more expensive metals like bronze or brass while offering cost-effective solutions for artists. The ability to cast intricate textures and fine details with zinc alloys adds a layer of complexity to sculptural creations.

Titanium, known for its remarkable strength-to-weight ratio and corrosion resistance, is emerging as an avant-garde choice for die casting sculptures. While it presents unique challenges in terms of casting, sculptors who embrace titanium can craft pieces that blend futuristic aesthetics with unrivaled durability.

The world of die casting materials is a diverse and exciting one, offering sculptors a palette of options to explore. Each material brings its own set of advantages and challenges, allowing artists to make informed choices that align with their artistic vision and objectives.

Design Considerations for Die Casting Sculptures

Creating a masterpiece through die casting sculpture goes beyond just selecting the right materials and technology—it requires careful consideration of design elements that make a piece truly exceptional. Design choices play a pivotal role in determining the aesthetics, functionality, and overall impact of a sculpture.

One of the fundamental design considerations in die casting is the choice of form and composition. Artists must envision how the sculpture will interact with its surroundings and its viewers. Whether it's an abstract piece meant to evoke emotions or a figurative sculpture telling a story, the form should resonate with the intended audience and convey the artist's message effectively.

Scale and proportion are critical aspects of design in die casting sculpture. Sculptors must determine the ideal size and scale of their piece based on its intended location and purpose. Large-scale outdoor sculptures, for example, require different considerations than smaller indoor pieces. Maintaining proper proportions ensures that the sculpture appears visually pleasing and harmonious within its environment.

Texture and surface finish are also essential design considerations. The die casting process allows for a wide range of textures, from smooth and polished to rough and textured. Artists must carefully select the appropriate finish that complements the subject matter and the emotions they want to convey. Texture can add depth and intrigue to a sculpture, inviting viewers to engage with it on a tactile level.

Furthermore, consideration of the sculpture's visibility from various angles is crucial. In many cases, die-cast sculptures will be viewed from multiple perspectives, so artists must ensure that their piece maintains its visual appeal and storytelling from every angle. This requires a keen understanding of three-dimensional design and the ability to create a sculpture that remains captivating and intriguing from all viewpoints.

Additionally, artists should think about the sculpture's structural integrity. The design must accommodate the stresses and strains the sculpture will experience, particularly for outdoor installations exposed to environmental factors. Sculptors need to work closely with engineers to ensure that the piece remains stable and safe over time.

The incorporation of lighting and shadow is another dimension of design that can elevate the impact of a die-cast sculpture. Strategically placed lighting can enhance the sculpture's visual appeal, create dramatic effects, and add a layer of dynamism to the artwork, especially in outdoor settings.

Overall, successful die casting sculpture relies on a harmonious marriage of materials, technology, and design. Sculptors who meticulously consider these design elements can create works of art that not only impress with their technical precision but also resonate deeply with viewers on an emotional and aesthetic level.

.png)

Case Studies of Successful Die Casting Sculptures

To truly understand the power and potential of die casting in the world of sculpture, let's explore some remarkable case studies that showcase the versatility and creativity of this art form.

Case Study 1: "The Spirit of Flight" by Leonardo Da Vinci

One of the most iconic examples of die casting in sculpture dates back to the Renaissance era, and it involves none other than the legendary artist Leonardo da Vinci. "The Spirit of Flight," also known as "Il Cavallo Rampante," is a masterpiece that exemplifies the early use of die casting techniques.

Da Vinci's sculpture, created in the late 15th century, represents a horse rearing on its hind legs with a rider. The artist's intricate design required a level of precision that was groundbreaking for its time. To achieve the detailed features of the horse and rider, including their flowing hair and elaborate armor, da Vinci employed a form of die casting using a lost-wax process.

In this process, a wax model of the sculpture was coated in a ceramic shell, and the wax was then melted away, leaving behind a hollow mold. Molten bronze was poured into this mold, resulting in a precise and intricate casting. This method allowed da Vinci to capture the lifelike details of "The Spirit of Flight" that remain awe-inspiring to this day.

Case Study 2: "Cloud Gate" by Anish Kapoor

Moving forward to the modern era, "Cloud Gate" by British-Indian sculptor Anish Kapoor is a testament to the innovation and creative possibilities offered by die casting. This iconic sculpture, also known as "The Bean," stands as a centerpiece in Chicago's Millennium Park.

"Cloud Gate" is a colossal, polished stainless-steel sculpture that seamlessly reflects its surroundings and the city skyline. What makes this sculpture a remarkable feat of die casting is the use of multiple seamless plates in its construction. Kapoor's vision required a surface without visible seams, which was achieved through precision die casting and meticulous finishing.

The die casting process allowed for the creation of individual plates that were seamlessly welded together to create the monolithic form. The result is a mirror-like surface that appears almost liquid, inviting viewers to interact with their reflections and the urban environment in a unique way.

Case Study 3: "RapidCaster" by Contemporary Sculptors

In recent years, contemporary sculptors have been pushing the boundaries of die casting technology through projects like "RapidCaster." This innovative approach combines 3D printing with die casting to create highly detailed and intricate sculptures in a fraction of the time compared to traditional methods.

The "RapidCaster" project involves the creation of 3D-printed wax models that serve as the basis for the die casting process. These wax models are generated with incredible precision, capturing the finest details of the artist's design. Once the wax model is completed, it is encased in a ceramic shell, and molten metal is poured into the mold, resulting in a high-quality casting.

The advantage of "RapidCaster" lies in its ability to rapidly produce intricate sculptures, making it a game-changer for artists looking to create complex and highly detailed works. This case study highlights how die casting continues to evolve and adapt to contemporary artistic needs, combining cutting-edge technology with traditional craftsmanship.

These case studies demonstrate the versatility and enduring relevance of die casting in the world of sculpture. From the Renaissance era to modern times, artists have harnessed the precision and creative potential of die casting techniques to create sculptures that inspire awe, engage viewers, and leave a lasting legacy in the world of art.

Die Casting vs. Traditional Sculpting Methods

The choice between die casting and traditional sculpting methods is a decision that artists must carefully consider, as each approach offers its own set of advantages and limitations. Let's delve into a comparative exploration of die casting and traditional sculpting methods to shed light on their respective merits.

Die Casting: Precision and Efficiency

Die casting unquestionably excels in terms of precision and efficiency. The use of sophisticated molds and automated machinery ensures that every casting is consistent, with intricate details faithfully replicated. This level of precision is particularly valuable for artists who seek to capture realism or convey intricate textures in their sculptures.

Furthermore, die casting is highly efficient, enabling artists to produce multiple castings of the same sculpture with minimal effort and time. This efficiency is a significant advantage for artists looking to create editions of their work or meet the demands of commercial projects. Die casting's ability to streamline the production process can be a game-changer for artists seeking both quality and quantity.

The availability of a wide range of materials in die casting, from aluminum to bronze, also provides artists with versatility in their creative choices. This versatility allows sculptors to experiment with different aesthetics and explore various artistic visions.

Traditional Sculpting Methods: Artisanal Craftsmanship

On the other hand, traditional sculpting methods offer a unique appeal rooted in artisanal craftsmanship. Sculptors who work by hand with materials like clay, marble, or wood have the opportunity to infuse their creations with a tangible sense of their own touch and personality. This hands-on approach allows for a deep connection between the artist and the sculpture.

Traditional sculpting methods also offer the freedom to work spontaneously and make adjustments on the fly. Unlike die casting, which requires meticulous planning and mold creation, traditional sculptors can adapt and refine their work as they go, responding to their intuition and artistic inspiration.

Moreover, traditional sculpting methods can result in one-of-a-kind, irreplaceable pieces of art. The inherent uniqueness of handcrafted sculptures often adds to their perceived value and appeal, attracting collectors and art enthusiasts who appreciate the authenticity and individuality of each work.

However, it's essential to acknowledge that traditional sculpting methods can be time-consuming and physically demanding. Artists working with stone or wood, for instance, require considerable skill and patience to shape their materials into their desired forms.

In summary, the choice between die casting and traditional sculpting methods ultimately depends on the artist's goals, artistic vision, and preferences. Die casting excels in precision, efficiency, and scalability, making it a practical choice for artists seeking reproducibility and commercial viability. On the other hand, traditional sculpting methods offer a more intimate and hands-on approach, allowing artists to imbue their work with a unique character and artistic depth. Many contemporary sculptors even find ways to blend these two approaches, using die casting for the creation of intricate parts or details and then incorporating handcrafted elements to add a personal touch to their sculptures.

Training and Education for Die Casting Sculptors

Becoming a proficient die casting sculptor requires a combination of artistic talent, technical expertise, and a deep understanding of the die casting process. Aspiring sculptors who wish to master this craft should consider pursuing formal training and education to equip themselves with the necessary skills and knowledge.

-

Artistic Foundation: The journey of a die casting sculptor begins with a strong foundation in art. This includes a deep understanding of form, composition, and aesthetics. Prospective sculptors should explore various art disciplines, such as drawing, painting, and traditional sculpting, to develop their artistic sensibilities.

-

Technical Training: Mastery of the die casting process is essential. Enrolling in courses or apprenticeships that focus on die casting techniques, mold making, and metalworking is crucial. Learning how to create and manipulate molds, pour molten metal, and finish castings with precision are fundamental skills for die casting sculptors.

-

Materials Knowledge: Understanding the properties and characteristics of different casting materials is vital. Sculptors should learn about the alloys commonly used in die casting, such as aluminum, bronze, and zinc, and how to work with them effectively.

-

Computer-Aided Design (CAD): In the digital age, proficiency in CAD software is indispensable. Artists should acquire skills in 3D modeling and design software, which are often used to create intricate sculpture designs and mold patterns.

-

Safety and Environmental Awareness: Die casting involves working with high temperatures and potentially hazardous materials. Training in safety protocols and environmental regulations is essential to ensure a safe and sustainable working environment.

-

Business and Marketing Skills: For sculptors looking to turn their passion into a career, business and marketing skills are invaluable. Learning how to promote one's work, manage finances, and navigate the art market are essential aspects of a successful artistic career.

-

Continual Learning and Networking: The world of art is ever-evolving, and die casting sculptors should stay updated on the latest techniques and technologies. Networking with fellow artists, attending workshops, and participating in exhibitions can provide valuable insights and opportunities for growth.

-

Mentorship: Seeking guidance from experienced die casting sculptors or mentors in the field can accelerate one's learning curve. Mentorship provides the opportunity to gain real-world insights and benefit from the wisdom of seasoned artists.

-

Practice and Persistence: Ultimately, becoming a skilled die casting sculptor requires dedication and practice. Artists should be prepared for a journey of trial and error, where each project serves as an opportunity to refine their craft and develop their unique artistic voice.

In conclusion, the path to becoming a proficient die casting sculptor involves a multidisciplinary approach that combines artistic talent with technical expertise and continuous learning. Formal education, practical experience, and a commitment to honing one's skills are all essential components of a successful career in die casting sculpture.

Conclusion: The Future of Die Casting in the World of Sculpture

As we reflect on the evolution, benefits, innovations, materials, design considerations, case studies, and training in the world of die casting sculpture, it becomes evident that this art form has a bright and promising future. Die casting has transcended its historical boundaries, becoming a dynamic and indispensable tool for contemporary sculptors and artists alike.

The future of die casting in sculpture holds exciting possibilities. Advancements in technology, such as 3D printing and CAD/CAM software, will continue to empower artists to create sculptures with unprecedented precision and complexity. These technologies will not only streamline the design and production process but also offer sculptors greater creative freedom.

Innovations in materials science will open up new frontiers for die casting sculpture. The development of novel alloys and composite materials will enable artists to experiment with unique properties, textures, and finishes, pushing the boundaries of what is achievable in sculptural art.

Furthermore, the sustainability of die casting aligns with the growing global emphasis on eco-conscious practices. Artists who prioritize environmental responsibility will find die casting an appealing choice, as it allows for efficient material usage, recycling, and reduced waste.

The future of die casting sculpture also includes increased accessibility and collaboration. Artists from diverse backgrounds and locations can connect and collaborate on projects with ease, thanks to digital communication and online platforms. This interconnectedness will foster a global community of die casting sculptors who inspire and challenge one another to reach new heights.

In conclusion, the future of die casting in the world of sculpture is characterized by innovation, collaboration, and a continued commitment to artistic excellence. As technology evolves and artists continue to push the boundaries of their craft, we can anticipate witnessing a new era of sculptural masterpieces that captivate audiences, inspire emotions, and leave an indelible mark on the world of art. Die casting will remain an invaluable tool in the artist's arsenal, enabling them to transform their visions into tangible works of beauty and meaning for generations to come.

FAQ 1: What is Die Casting and How Does It Work?

Keywords: Die casting, manufacturing process, metal components, mold, high pressure, alloys

Subheadings:

- Introduction to Die Casting: Learn the basics of the die casting process.

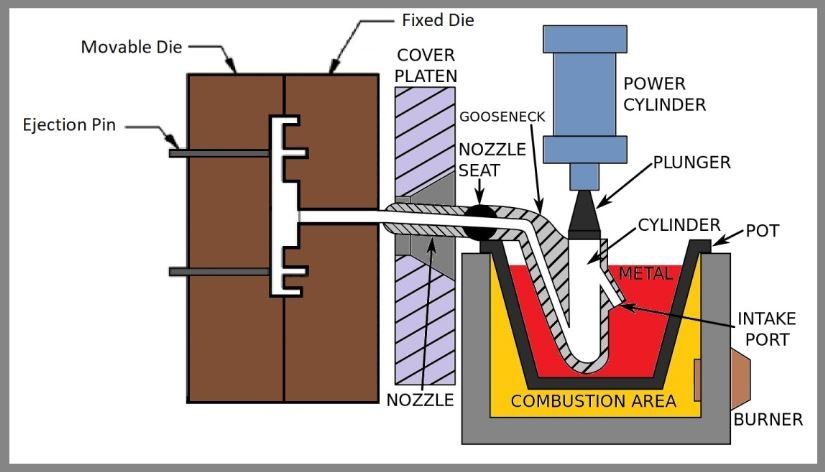

- Working Principle: Understand how die casting molds work under high pressure.

- Materials Used: Discover the common alloys used in die casting.

- Advantages of Die Casting: Explore the benefits of choosing die casting for your manufacturing needs.

- Applications: Find out where die casting is commonly used in various industries.

FAQ 2: What Are the Different Types of Die Casting?

Keywords: Die casting methods, cold chamber, hot chamber, squeeze casting, semi-solid

Subheadings:

- Cold Chamber Die Casting: Learn about the process and applications of cold chamber die casting.

- Hot Chamber Die Casting: Explore the advantages and limitations of hot chamber die casting.

- Squeeze Casting: Understand how squeeze casting differs from traditional die casting methods.

- Semi-Solid Die Casting: Discover the benefits of using semi-solid die casting techniques.

- Choosing the Right Method: Tips for selecting the appropriate die casting method for your project.

FAQ 3: What Are the Quality Control Measures in Die Casting?

Keywords: Quality control, die casting defects, inspection techniques, precision, consistency

Subheadings:

- Quality Control Importance: Understand why quality control is crucial in die casting.

- Common Defects: Learn about typical defects and issues in die casting.

- Inspection Techniques: Explore methods for inspecting die-cast parts with precision.

- Maintaining Consistency: Discover how to ensure consistent quality in die casting.

- Certifications: Find out about industry certifications related to die casting quality standards.

FAQ 4: What Are the Advantages of Aluminum Die Casting?

Keywords: Aluminum die casting, lightweight, corrosion resistance, cost-effective, complex shapes

Subheadings:

- Aluminum Die Casting Benefits: Explore the unique advantages of using aluminum for die casting.

- Lightweight Components: Learn how aluminum die casting produces lightweight parts.

- Corrosion Resistance: Understand how aluminum's natural properties resist corrosion.

- Cost-Effectiveness: Discover how aluminum die casting can be a cost-effective choice.

- Complex Shapes: See how aluminum die casting allows for intricate and complex designs.

FAQ 5: How Can I Choose the Right Die Casting Supplier?

Keywords: Die casting supplier, supplier selection, quality assurance, production capacity, experience

Subheadings:

- Assessing Supplier Credentials: Learn how to evaluate a die casting supplier's qualifications.

- Quality Assurance Practices: Discover the importance of a supplier's quality control measures.

- Production Capacity: Consider factors like capacity and lead times when selecting a supplier.

- Industry Experience: Explore the benefits of choosing a supplier with extensive die casting experience.

- Requesting Quotes: Understand the process of requesting quotes and comparing supplier offerings.

GET QUOTE

- Visit our website: https://www.nbyichou.com/

- Email us: [email protected]

- Call us/whatsapp: +86 13355741031

- Chat with us: Live chat support available on our website