Introduction

Tooling manufacturing plays a crucial role in modern production, encompassing the creation of tools that are integral to shaping, cutting, and forming materials in various industries. Whether it's molds, dies, jigs, or specialized fixtures, tooling is essential for ensuring the precision and efficiency of mass production. Tooling not only influences the quality of the final product but also affects the cost and speed of the manufacturing process.

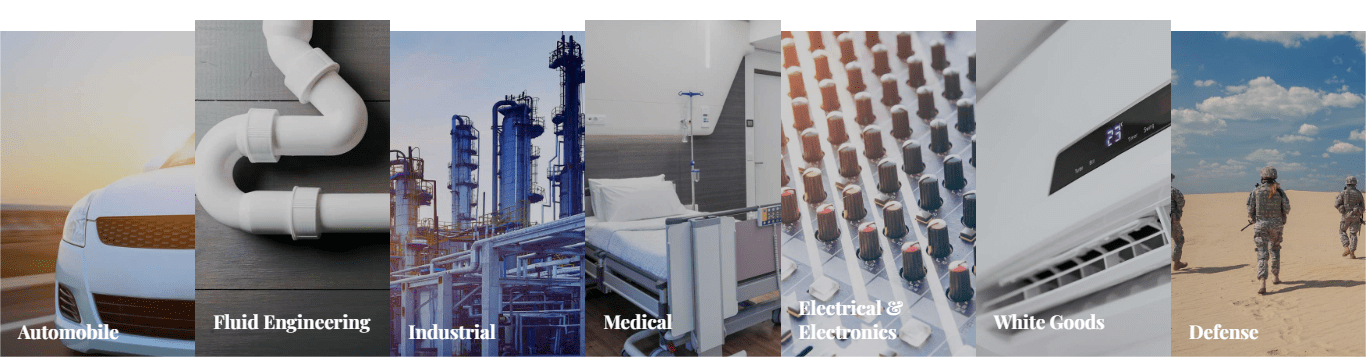

In high-precision sectors like automotive, aerospace, medical, and industrial applications, tooling is particularly vital. In these industries, where safety, reliability, and performance are non-negotiable, using the right tooling ensures that every component meets the strictest standards. From the creation of intricate automotive parts to advanced aerospace components, tooling allows manufacturers to deliver high-quality products consistently and cost-effectively.

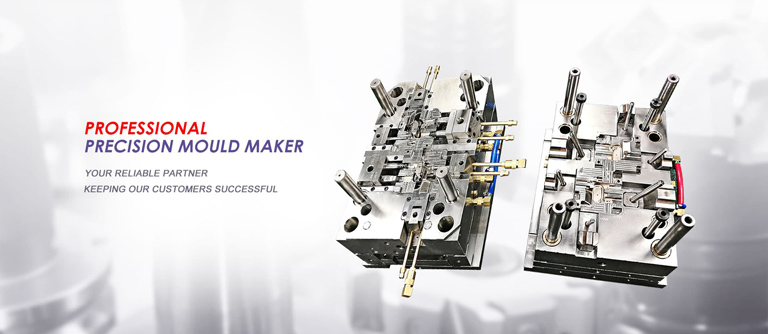

At YICHOU, we specialize in providing high-quality tooling solutions that cater to diverse industries. With decades of expertise in tooling manufacturing, we are committed to delivering precision-engineered tools that enhance production efficiency and product quality. Our tooling solutions are designed to meet the unique demands of each client, ensuring optimal results in every project we undertake.

What Is Tooling Manufacturing?

Tooling manufacturing refers to the process of designing, creating, and maintaining tools that are used in the production of parts and components in various industries. These tools include molds, dies, jigs, fixtures, cutting tools, and CNC machines, all of which are essential for shaping, forming, or machining raw materials into precise final products. Tooling plays a fundamental role in enabling mass production, ensuring that each part produced meets the desired specifications.

The Role of Tooling in the Production Process

Tooling is critical in the production process as it directly affects the ability to manufacture parts accurately and consistently. It ensures that the production process is efficient, cost-effective, and scalable. The role of tooling spans across multiple stages of manufacturing—from prototyping to mass production. Properly designed tools help streamline production, reduce waste, and maintain high standards of quality. They also facilitate the automation of production, increasing output and reducing human error.

In industries that require high precision, such as aerospace, automotive, medical, and industrial manufacturing, tooling ensures that complex designs and tolerances are met reliably. Whether it’s a simple part or an intricate, customized component, the right tooling is essential for achieving the desired outcome.

How Tooling Impacts Product Quality, Cost Efficiency, and Time Management

-

Product Quality: The quality of the tools used in production directly impacts the final product’s quality. High-quality tooling ensures that parts are consistently made with the correct dimensions, surface finishes, and features, reducing the likelihood of defects and rework. Precision tooling minimizes the risks of defects that could compromise the functionality or safety of the product, which is crucial in industries like aerospace and medical manufacturing.

-

Cost Efficiency: Tooling is a significant upfront investment, but its impact on long-term cost efficiency cannot be overstated. With the right tooling, production runs can be optimized, reducing waste and minimizing costly errors. High-quality tools also improve the longevity of equipment, lowering maintenance and replacement costs. Additionally, efficient tooling speeds up production cycles, helping businesses save on labor and operating costs.

-

Time Management: Time is a crucial factor in manufacturing, and tooling helps optimize production timelines. Well-designed tools streamline processes and reduce the time needed for setup, adjustments, and changes between production runs. This allows manufacturers to meet tight deadlines and keep up with demand. In turn, faster production translates into greater productivity and higher throughput, ultimately improving the bottom line.

At YICHOU, we understand the vital role tooling plays in delivering high-quality products on time and within budget. Our precision tooling solutions are designed to meet the specific needs of each client, helping them enhance product quality, optimize costs, and meet production deadlines efficiently.

The Different Types of Tooling in Manufacturing

Tooling plays a vital role in the manufacturing process, and selecting the right type of tooling is essential for achieving optimal production efficiency, cost-effectiveness, and product quality. There are several types of tooling, each serving a specific function in various stages of production. Below are some of the most common types of tooling used in manufacturing:

1. Molds

Molds are used primarily in casting, molding, or injection-molding processes. They are hollow forms into which molten material—such as metal, plastic, or rubber—is poured and allowed to solidify, taking the shape of the mold. Molds are crucial in industries like automotive, consumer products, and medical devices, where high volumes of identical parts are needed.

- Example: Injection molds are used in the mass production of plastic components, such as car parts or packaging products.

2. Dies

Dies are used in processes such as stamping, punching, bending, or forging to shape or cut material, often metal. Dies are typically used for producing parts with consistent shapes and dimensions. Dies are essential in industries like automotive and electronics, where precision and high-volume production are required.

- Example: A stamping die is used to cut out automotive body parts from sheets of metal.

3. Jigs

Jigs are custom-made tools used to hold and position workpieces during machining or assembly. Unlike fixtures, which only hold parts, jigs guide tools to ensure accuracy during operations like drilling, milling, or cutting. Jigs are crucial in scenarios where multiple identical parts need to be processed.

- Example: A drilling jig is used to ensure accurate hole placement in a series of metal components.

4. Fixtures

Fixtures are devices used to securely hold a workpiece in place during a manufacturing process. Unlike jigs, fixtures do not guide tools; their primary purpose is to ensure stability and consistency in positioning. Fixtures are especially useful in operations that require high precision or when parts need to be aligned repeatedly.

- Example: A fixture used in CNC machining holds the part in place while the machine performs operations like milling or turning.

5. CNC Tools

CNC (Computer Numerical Control) tools are specialized machines that use computer-controlled movements to perform a wide range of manufacturing operations such as cutting, drilling, or shaping. CNC tooling is widely used in industries that require high precision, including aerospace, automotive, and medical device manufacturing.

- Example: CNC lathes and milling machines are used for precision machining of metal parts, such as turbine blades or engine components.

6. Other Tooling Types

- Cutting Tools: These tools are used in processes like turning, milling, or drilling to remove material from the workpiece.

- Assembly Tools: Used for assembling parts, these tools ensure accurate and consistent assembly during production runs.

Importance of Choosing the Right Tooling for Specific Production Needs

The selection of tooling depends heavily on the specific needs of the production process. The right tooling can significantly impact the overall efficiency, cost-effectiveness, and quality of the final product. Here are a few key factors to consider when choosing tooling:

-

Material Type: Different materials require different tooling to achieve the desired finish and precision. For example, a mold for plastic injection will be very different from a die for metal stamping.

-

Production Volume: For high-volume production, selecting the right tooling, such as robust dies or molds, is crucial to ensure long-term durability and cost-efficiency. For lower volumes or prototype runs, it might be more beneficial to choose more flexible tools or methods, like 3D printing for molds.

-

Precision and Tolerance: If the production requires tight tolerances, such as in the aerospace or medical industries, investing in high-precision tools like CNC machines or custom-made jigs may be necessary to achieve the required accuracy.

-

Production Speed: Choosing the right tooling is essential for ensuring that production cycles are as fast as possible without compromising quality. For example, an automated fixture might speed up the manufacturing process, whereas manual jigs might be more suited for small-batch production.

At YICHOU, we specialize in providing the right tooling solutions tailored to the specific needs of our clients. Whether it’s a custom mold, die, fixture, or CNC tool, we ensure that each piece of tooling is designed for maximum performance, efficiency, and precision in your production process.

Tooling Cost: What to Expect

Tooling is often one of the largest upfront investments in the manufacturing process. While it may represent a significant cost initially, the right tooling can lead to improved efficiency, reduced defects, and long-term cost savings. Understanding the breakdown of tooling costs and how to optimize them is essential for managing your production budget effectively.

Breaking Down Tooling Costs

-

Design Costs

- Tooling design is a critical step that involves creating detailed plans and specifications for the tooling. This includes considerations such as material selection, tolerances, part complexity, and the type of manufacturing process.

- Cost Factors: The complexity of the design, the number of iterations needed, and the expertise of the design team all influence the cost.

- Example: Designing a complex die for a high-precision aerospace part will require more time and expertise than designing a simple mold for consumer plastic products.

-

Material Costs

- The choice of material used for tooling plays a major role in the overall cost. Tooling materials need to be durable enough to withstand repeated use, but also cost-effective.

- Cost Factors: The type of material (e.g., steel, carbide, aluminum), its availability, and the required quality standards all impact material costs.

- Example: High-grade steel or carbide for cutting tools or molds will be more expensive than aluminum, but they are necessary for high-precision applications like aerospace or medical device manufacturing.

-

Labor Costs

- Labor costs are associated with the time spent on designing, producing, and testing the tooling. Skilled labor is required to create, assemble, and refine tooling to meet exact specifications.

- Cost Factors: The level of expertise required, the complexity of the tooling, and the number of personnel involved will affect labor costs.

- Example: CNC machine operators or toolmakers with specialized skills may command higher wages, increasing labor costs, but their expertise is essential for high-precision tooling.

-

Manufacturing and Setup Costs

- Once the tooling is designed and materials are sourced, there are costs associated with manufacturing the tool itself. These costs include machine time, equipment usage, and setup time.

- Cost Factors: The production volume, setup time for machinery, and the type of tooling being produced all affect these costs.

- Example: Manufacturing a mold for injection molding typically requires substantial setup time on CNC machines, which adds to the overall tooling cost.

-

Maintenance and Repair Costs

- Tooling will naturally wear out over time, especially with high-volume production. Regular maintenance is required to ensure tooling operates efficiently and remains in good working condition.

- Cost Factors: The frequency of use and the durability of the material determine the cost of maintenance. Higher-quality tools may require less frequent repairs but may come with a higher initial cost.

- Example: A mold for mass production of automotive parts might require more frequent maintenance than a die for low-volume production, impacting the overall cost of ownership.

How to Optimize Tooling Costs and Manage Your Budget Efficiently

-

Choose the Right Tooling for Your Production Needs

- Select tooling based on the specific requirements of your production process. For example, if you need high-volume production with precision, investing in durable, high-quality tooling will save you money in the long run due to fewer repairs and longer tool life.

- Tip: Evaluate the total cost of ownership over the life of the tool, not just the initial investment.

-

Work with Experienced Tooling Suppliers

- Partnering with experienced tooling manufacturers like YICHOU can help ensure that your tooling is designed efficiently, with a focus on cost-effectiveness and longevity. Skilled suppliers can offer design optimization to reduce unnecessary costs while maintaining quality.

- Tip: Collaborate with your supplier during the design phase to explore cost-saving options without compromising on performance.

-

Invest in Multi-Purpose or Flexible Tooling

- Consider investing in multi-purpose tooling that can handle different tasks or be easily adapted for different products. This reduces the need for a large number of specialized tools and can lower costs.

- Example: Modular tooling systems can often be reconfigured for different parts, offering flexibility in production runs.

-

Streamline Tooling Maintenance

- Regular and proactive maintenance of tooling can extend the life of tools and reduce costly repairs. Implementing a maintenance schedule and monitoring tool performance ensures that tools are in optimal condition, which can save on unexpected downtime and repairs.

- Tip: Use advanced monitoring tools to track the wear and tear on your tooling and schedule maintenance before it becomes a costly issue.

-

Optimize Production Volume

- When tooling is designed for high-volume production, unit costs can decrease as the volume increases. For long-term production runs, investing in durable tooling that can handle large quantities efficiently may save money in the long run.

- Tip: Evaluate the balance between tooling cost and expected production volume to determine the most cost-effective solution for your needs.

At YICHOU, we focus on providing cost-effective tooling solutions that maximize efficiency while maintaining the highest quality standards. Our expertise in tooling design, materials selection, and production ensures that your tooling investments are optimized for long-term success.

What Does Tooling Mean in Engineering?

In engineering, tooling refers to the tools, molds, dies, and machinery used to create parts or components during the manufacturing process. Tooling is integral to product design, ensuring that the components are fabricated with the highest precision and meet specific functional and aesthetic requirements. The role of tooling in engineering is to transform the designer's vision into a tangible, manufacturable product that meets stringent quality standards.

Tooling’s Role in Product Engineering and Design

Tooling bridges the gap between conceptual design and mass production. During the product engineering phase, designers collaborate with tooling experts to ensure that the product can be manufactured efficiently, cost-effectively, and accurately. The design phase includes selecting the appropriate tooling methods and materials that will enable the production of the part at scale, while maintaining tight tolerances and quality.

Effective tooling ensures that the final product meets both functional and aesthetic requirements set by the engineers and designers. For example, in the automotive industry, tooling is used to create parts that not only fit perfectly within the vehicle assembly but also meet safety and durability standards. Similarly, in aerospace engineering, tooling plays a critical role in fabricating parts that can withstand extreme conditions while maintaining structural integrity.

In the development of a product, precise tooling is designed to facilitate:

- Consistency: Ensuring that each part produced is identical and meets the required specifications.

- Efficiency: Reducing production time and waste by optimizing tooling design and manufacturing processes.

- Feasibility: Making sure that the product can be produced at scale while maintaining high quality and reducing costs.

The Importance of Precise Tooling for Achieving High-Quality Manufacturing Outcomes

Precise tooling is essential for ensuring the production of high-quality components that meet the tight tolerances and specifications required in modern engineering. The role of precise tooling extends across multiple facets of the manufacturing process:

-

Dimensional Accuracy: Tooling ensures that parts are manufactured with the exact dimensions required. In industries like aerospace and medical device manufacturing, even small deviations in dimensions can lead to performance issues, compromised safety, or system failures. Precision tooling ensures that parts fit together correctly, function as intended, and are compliant with industry regulations.

-

Surface Finish and Quality: The quality of the tooling directly impacts the surface finish of the final product. Whether it's a smooth, polished surface for aesthetic purposes or a textured finish for grip and durability, tooling must be designed to achieve the desired surface quality consistently. In industries like automotive or medical devices, surface imperfections can affect the product's functionality or its marketability.

-

Material Utilization: Properly designed tooling ensures efficient use of materials, reducing waste and lowering production costs. For example, injection molds are designed to minimize material waste during the molding process, contributing to both cost savings and environmental sustainability.

-

Tool Longevity: The precision of tooling also contributes to its durability. High-quality tooling is designed to withstand repeated use, reducing downtime and the need for frequent replacements. This is particularly critical for industries that require high-volume production, such as electronics or automotive manufacturing.

-

Consistency Across Batches: Tooling is essential for ensuring consistency when producing large quantities of a product. Whether it's the creation of identical parts in a short time frame or producing a high volume of components for an ongoing project, precise tooling helps achieve uniformity and reduces variability in the final product.

At YICHOU, we specialize in providing engineering solutions that focus on high-precision tooling to meet the specific needs of our clients. With our expertise in designing and manufacturing tooling for various industries, we help ensure that your product is produced with the highest level of accuracy, quality, and efficiency.

Tooling vs. Machining: What’s the Difference?

Though closely related, tooling and machining are two distinct yet complementary concepts in the manufacturing process. Both play vital roles in transforming raw materials into finished parts, but they serve different purposes and require different types of equipment and expertise.

What is Tooling?

Tooling refers to the tools, dies, molds, jigs, fixtures, and machinery that are used to shape, form, or cut materials into the desired specifications during the production process. Tooling is designed and produced prior to or in the early stages of manufacturing, serving as the foundation for the mass production of parts. Tooling is often custom-made based on the design requirements of the part, ensuring that it meets the necessary dimensional tolerances and material specifications.

Tooling’s primary purpose is to enable efficient and precise production. In essence, tooling is about providing the necessary “equipment” or “devices” that are needed for shaping and forming raw materials into parts. Examples of tooling include molds for injection molding, dies for stamping, jigs for holding parts during machining, and CNC machines for automated cutting.

What is Machining?

Machining is a process that involves removing material from a workpiece to achieve the desired shape, size, and surface finish. Machining uses tools (often referred to as "cutting tools") to precisely remove material from the raw material, typically metals, plastics, or composites. Unlike tooling, machining is an operational process that happens after the tooling is set up and ready for use.

Common machining processes include:

- Turning: Rotating the workpiece against a cutting tool to remove material.

- Milling: Using a rotating tool to cut away material from a workpiece.

- Drilling: Creating holes by rotating a drill bit.

- Grinding: Using a grinding wheel to smooth and finish surfaces.

Machining focuses on achieving tight tolerances and high-quality finishes, ensuring that parts meet specific design and functionality requirements.

How Tooling and Machining Complement Each Other

While tooling and machining are distinct processes, they work together in a complementary way to produce high-quality components. Tooling provides the framework, and machining provides the precision needed for fine-tuning parts to exact specifications.

-

Tooling Creates the Framework for Machining

- Tooling sets the foundation for machining by holding and positioning the workpiece accurately. For example, a fixture holds a part in place during machining, ensuring that it does not shift and that machining operations can be carried out accurately.

- Additionally, tooling like molds and dies provide the initial shaping of a part. In some cases, parts can be formed or cast with minimal machining required afterward.

-

Machining Fine-Tunes the Product

- Once the basic shape or form is created using tooling, machining is used to achieve the final, precise dimensions, surface finishes, and details. For instance, a die may be used to cut the shape of a metal component, but machining ensures that the part has the correct fit and finish for its intended application.

- Tooling ensures that parts are produced efficiently and in large quantities, while machining is focused on achieving accuracy, fine detail, and high-quality surface finishes.

-

Efficiency and Cost-Effectiveness

- Tooling helps streamline the production process by enabling the efficient production of parts, especially in high-volume manufacturing. Machining, on the other hand, is often used for more precise or low-volume runs where exact tolerances are required.

- By combining tooling and machining, manufacturers can achieve both high efficiency and high precision. Tooling minimizes the amount of machining needed, while machining ensures that any fine adjustments or high-precision details are accurately executed.

An Example in Action: Aerospace Industry

In the aerospace industry, tooling might involve the creation of custom molds and dies for complex metal parts, while machining processes such as CNC turning or milling are used to finalize the part with exact tolerances. Tooling is used to form the basic shape, and machining refines the part, ensuring that it can withstand the extreme conditions required for aerospace applications.

At YICHOU, we combine advanced tooling solutions with precise machining to ensure that every part we produce meets the highest standards of quality, efficiency, and performance. Whether you need tooling for mass production or machining for high-precision components, our expertise can meet the unique needs of your project.

Tooling for CNC: What You Need to Know

CNC (Computer Numerical Control) tooling is a critical component of modern manufacturing. CNC machines use computer programs to control the movement of cutting tools, enabling precise and automated production of complex parts. CNC tooling refers to the tools, inserts, and fixtures used in these machines to shape, cut, and finish materials with unparalleled accuracy.

CNC tooling is essential for industries that require high-precision parts, such as aerospace, automotive, medical devices, and electronics. Unlike traditional manual machining, CNC allows for repeatable accuracy and faster production cycles, which is why it has become a cornerstone of modern manufacturing.

Why CNC Tooling Is Important

-

Precision and Accuracy CNC tooling ensures that parts are manufactured to exact specifications with tight tolerances. The ability to repeat complex operations with the same level of precision is a key advantage of CNC over traditional machining. This is especially important in industries like aerospace, where even the slightest variation in part dimensions can lead to safety issues or performance problems.

-

Efficiency and Speed CNC machines can operate continuously and with minimal downtime, significantly increasing production speed. CNC tooling, such as carbide inserts and multi-functional cutting tools, ensures that the machine performs these operations efficiently, reducing the time spent on each part. This high-speed production is ideal for high-volume manufacturing while maintaining the quality of the output.

-

Complexity of Parts CNC tooling is essential for creating complex shapes and geometries that would be impossible or extremely difficult to achieve manually. The use of specialized CNC tools allows for intricate designs, precise cuts, and detailed surface finishes that meet the demands of industries requiring highly detailed components.

-

Consistency and Repeatability With CNC tooling, once a part is programmed, the same result can be achieved every time, making it ideal for large production runs or creating components that need to adhere to strict standards. This consistency eliminates human error and improves the overall quality of the finished product.

How CNC Tooling Affects the Manufacturing Process

-

Tool Selection The right CNC tooling plays a crucial role in the success of the manufacturing process. Choosing the appropriate cutting tool, insert material, and tool geometry ensures that the CNC machine operates at peak efficiency. For instance, carbide tools are often used for hard materials like stainless steel, while high-speed steel might be selected for softer metals.

-

Tooling Setups CNC tooling setups must be carefully planned to ensure optimal performance and minimal machine downtime. The use of custom fixtures and toolholders allows for quick tool changes and accurate part positioning, ensuring that the CNC machine operates smoothly throughout the production cycle.

-

Tool Wear and Maintenance Over time, CNC tools wear out due to continuous cutting and high-stress conditions. Regular monitoring of tool wear and timely replacement of cutting tools are crucial for maintaining the accuracy and efficiency of the CNC machine. Advanced monitoring systems can track tool performance, alerting operators when maintenance is required.

-

Optimization for Materials CNC tooling is designed for use with a wide range of materials, including metals, plastics, composites, and ceramics. The material being processed determines the type of tooling used, with specialized tools required for harder materials, while softer materials might require tools designed for faster cutting. Proper tool selection based on material type ensures that the process is as efficient as possible while maintaining high-quality outcomes.

How YICHOU Can Help with High-Precision CNC Tooling for Various Industries

At YICHOU, we specialize in providing high-precision CNC tooling solutions tailored to meet the demands of various industries. Our expertise in CNC tooling ensures that our clients receive tooling that enhances both the efficiency and accuracy of their manufacturing processes. Here’s how YICHOU can assist with your CNC tooling needs:

-

Custom Tooling Design We offer custom CNC tooling solutions, designed to meet the specific requirements of your manufacturing process. Whether you need tooling for a unique part, a complex shape, or a specialized material, our team works closely with you to develop the right solution.

-

Tooling for Complex Applications From aerospace components to medical devices, we provide tooling for industries that require high precision and performance. Our tools are designed to handle complex geometries and tight tolerances, ensuring your parts meet the highest quality standards.

-

Material-Specific Tooling YICHOU understands the importance of selecting the right tooling for the materials you're working with. We offer tooling designed for a variety of materials, including metals, plastics, and composites, ensuring that each project is completed efficiently with optimal results.

-

Quality Assurance Our CNC tooling undergoes rigorous quality control checks to ensure that every tool meets the necessary standards for performance and durability. With a focus on high-precision manufacturing, we guarantee that your CNC tooling will perform consistently and provide long-lasting results.

-

Optimized Production By selecting the right tooling and ensuring efficient setups, we help streamline your CNC manufacturing process. This reduces downtime, minimizes tool wear, and enhances the overall productivity of your operations.

Whether you are in the aerospace, automotive, medical, or electronics industry, YICHOU provides the CNC tooling expertise and high-quality solutions that you need to achieve precision and efficiency in your manufacturing processes.

What Is Production Tooling?

Production tooling refers to the tools, equipment, and machines used in the mass production of parts and components. Unlike prototype tooling, which is designed to create a small number of parts for testing or evaluation, production tooling is designed for long-term use in large-scale manufacturing processes. Production tooling is made to withstand the stresses of high-volume production, ensuring that parts are produced efficiently, with consistent quality and at lower costs.

The significance of production tooling lies in its ability to streamline the manufacturing process. It enables the automation of tasks such as cutting, molding, stamping, or forming, significantly increasing production speed, reducing human error, and enhancing product consistency. Whether you're manufacturing car parts, consumer electronics, or industrial machinery, production tooling ensures that your products meet the required specifications while optimizing cost and time.

Differences Between Prototype Tooling and Production Tooling

-

Purpose

- Prototype Tooling: Created for testing and validating designs before full-scale production. It is usually used to produce a limited number of parts to assess functionality, design, and performance.

- Production Tooling: Built for mass production, capable of creating thousands or even millions of parts consistently and efficiently. It focuses on durability, high-volume output, and maintaining precise specifications over extended production runs.

-

Material and Durability

- Prototype Tooling: Typically made from less durable materials, as the tooling is not intended for high-volume use. It may be constructed from softer metals or even 3D printed materials for quick production.

- Production Tooling: Constructed from durable, long-lasting materials like hardened steel, carbide, or specialized alloys to withstand the wear and tear of continuous production processes.

-

Cost

- Prototype Tooling: Less expensive, as it’s designed for limited use and is often produced quickly with lower material costs.

- Production Tooling: More expensive due to the higher durability of materials, the complexity of the design, and the precision required for mass production.

-

Timeframe

- Prototype Tooling: Typically has a shorter lead time, as it’s designed for a small-scale test run and can be made quickly for validation purposes.

- Production Tooling: Requires a longer lead time due to its complexity and the need for precise engineering to ensure long-term reliability and functionality during high-volume production.

How YICHOU Handles Both Production and Prototype Tooling Needs

At YICHOU, we specialize in both prototype tooling and production tooling. We understand that each project comes with unique needs, whether you're developing a new product and need rapid prototypes, or you're scaling up for high-volume manufacturing. Here’s how we support both types of tooling:

-

Prototype Tooling Solutions

- We offer rapid tooling services that allow you to validate your product designs before committing to full-scale production. Whether it’s creating small batches for testing or fine-tuning a prototype, our team works quickly and efficiently to bring your designs to life.

- Our prototype tooling services include low-volume molds, dies, and 3D-printed tooling, enabling faster turnaround times and reduced costs for testing and evaluation.

-

Production Tooling Solutions

- Once your design is validated, we provide high-quality production tooling designed for large-scale manufacturing. We use durable materials and precision engineering to create tooling that can withstand the demands of mass production.

- From CNC machining to injection molding and stamping dies, we offer tailored solutions to meet the specific needs of your production process, ensuring that parts are manufactured efficiently, consistently, and at scale.

Choosing the Right Tooling Supplier: Why YICHOU?

Choosing the right tooling supplier is critical for ensuring your products are manufactured to the highest standards of quality and efficiency. Here’s why YICHOU is the ideal partner for your tooling needs:

-

Expertise in Both Prototype and Production Tooling

- With years of experience in designing and producing both prototype and production tooling, YICHOU provides the technical expertise required to support all stages of your product development process.

-

Quality Assurance

- At YICHOU, we are committed to delivering tooling solutions that meet the highest quality standards. Our rigorous quality control processes ensure that every tool we produce is tested and inspected to ensure precision and reliability.

- We use advanced testing methods to verify the accuracy of tooling before it is used in production, guaranteeing that every part produced meets your exact specifications.

-

Customer-Centric Approach

- We prioritize your needs and work closely with you to understand your requirements and deliver customized tooling solutions that maximize efficiency and performance. Our team is dedicated to offering flexible support and clear communication throughout the design and production process.

-

Industries We Serve

- YICHOU provides tooling solutions to a wide range of industries, including:

- Automotive: High-precision tooling for manufacturing car components, from engine parts to interior fittings.

- Aerospace: Tooling designed for the production of aerospace components that require strict quality standards and performance.

- Medical Devices: Precise tooling for producing medical devices and instruments, where accuracy and safety are paramount.

- Consumer Electronics: Tooling solutions for the mass production of components like circuit boards and plastic housings.

- YICHOU provides tooling solutions to a wide range of industries, including:

-

Successful Case Studies

- We have successfully partnered with numerous clients to deliver tooling solutions that optimize their production processes. For example, we helped an aerospace company reduce production time by 20% through the implementation of custom tooling, resulting in both cost savings and faster time-to-market.

Conclusion

In summary, production tooling is the backbone of large-scale manufacturing, ensuring efficient, high-quality production of parts and components. By understanding the differences between prototype tooling and production tooling, manufacturers can make informed decisions about the tooling solutions they need. At YICHOU, we offer both types of tooling with a focus on precision, durability, and efficiency, supporting industries from automotive to aerospace, medical devices, and beyond.

If you are looking for a reliable partner for your tooling needs, YICHOU is here to provide you with the expertise, quality, and customer-focused solutions you need. Contact us today to learn more about how we can assist with your tooling solutions and help you take your manufacturing to the next level.

Get Quote

- Email us: [email protected]

- Call us/whatsapp: +86 13355741031

- Chat with us: Live chat support available on our website